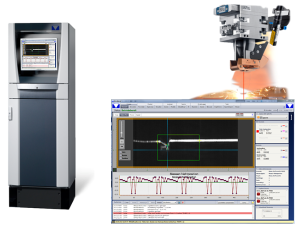

Precitec presented the YW52 laser welding head with integrated ScanTracker for the controlled weld position and weld seam width. In conjunction with the WeldMaster system for realtime process control and quality monitoring, this is a flexible and comprehensive solution for difficult welding tasks under changing conditions.

Precitec presented the YW52 laser welding head with integrated ScanTracker for the controlled weld position and weld seam width. In conjunction with the WeldMaster system for realtime process control and quality monitoring, this is a flexible and comprehensive solution for difficult welding tasks under changing conditions.

The WeldMaster measures the joining position laterally and the width of the gap. Instead of an external axis, the integrated scanner mirror of the ScanTracker precisely controls the focal position along the measured joint. Additionally, the mechanically-controlled collimation lens corrects any change in the standoff distance. The WeldMaster also controls the laser power, which is freely-programmable, in sync with the pendulum motion. This makes ScanTracker the ideal solution for applications involving differing weld seams or extensive retooling. The seam width is freely adjustable via an analog interface and requires no additional control.

Examples of the first successful applications of the WeldMaster system in automotive engineering are laser welding and the quality control of gear units, aluminium connections in the drive train, as well as aluminium fillet welds in body construction.