Specialized in the design and manufacturing of machines and automated lines for the production of electric motors, Dema is focusing its innovative skills in the ambit of the handling of the laminations composing stators and rotors and in the implementation of rotor and stator stacks.

Specialized in the design and manufacturing of machines and automated lines for the production of electric motors, Dema is focusing its innovative skills in the ambit of the handling of the laminations composing stators and rotors and in the implementation of rotor and stator stacks.

What will be the future of electric motors? How is changing the manufacturing process of electric motors? And how will that process be realized?

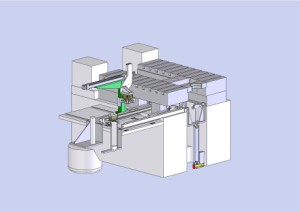

To provide answers to these requirements, Dema, headquarters in Varazze (Italy), is focusing its innovative skills in the ambit of the handling of the stator and rotor laminations and in the production of stator and rotor stacks. Requirements, the latter, that are generated by the automotive world, in the field of the production of the new motors used for the electric mobility. In this context, the company is intensifying its contribution given until now in the development of this applicative segment, extending operational advantages and benefits also to those sectors, including the household appliance industry, today ready to introduce and to welcome the same innovations as opportunities to win new market challenges.

Handling of laminations

In the blanking productive process of loose laminations, they are unloaded from the area under the blanking press through shaped pipes. The automation that Dema is developing and tuning will allow to check in real time the anomalies of the productive process, enabling operators to control possible problems of the blanking die or of the blanking process immediately. All that by eliminating the delay existing today in the control, owing to the use of shaped channels, with an operational approach that will lead to a significant efficiency rise in the blanking process and will allow maximising the material use.

Backlack technology

After supplying the very first automatic line for the production of stators and rotors using Backlack technology, Dema is developing new technologies as well, to automate and to optimize each phase of the manufacturing process. Concerning this, Dema is focusing its attention, research and development resources on the implementation of tools for the sizing process that can be filled, pressurized, opened and emptied without the operator’s intervention; use of induction heating to perform the thermal cycle; the final assembling of coiled T poles to form the stator.

Interlocked rotor and stator stacks

In case of production of interlocked rotor and stator stacks directly in the blanking press, it is necessary to timely control all the dimensional and geometrical characteristics of the produced stacks. For this purpose, Dema is developing compact control machines for the product control, to be positioned directly downstream of the blanking press, which use contactless and mechanical controls.

Welcome in the future of the electric motor production!