A group with 3 sand casting units, a chill casting division, robotized, where work 25 people, and international contracts with prestigious realities, European and United States in particular. This is the identity card of Fonderia Morini, historical company headquartered at Cotignola, in Ravenna province, which since 1959 has been representing a feather in the cap for the whole sector.

Fonderia Morini represents a real Italian excellence. Luca Morini, owner of the company, states: «We are a company that makes excellence and quality the distinguishing traits of its entrepreneurial character, and we have gained these characteristics by continuously raising the bar of the technical level, investing in technologies, in automation, in robotics and in people to produce more and more difficult, daring and demanding products. We made it».

A five-year job order with the company that manages the Los Angeles subway is only one of the examples witnessing the quality and the reliability of Fonderia Morini, which has always believed in automation. «Really. The first automated moulding line was installed in the company in 1983 and since then we haven’t given it up anymore. Not the line, but automation. Automation, standardization and constant controls, starting from the raw material acceptance ones, are the necessary conditions to reach that excellence that I have just mentioned. The quality and repeatability standard provided by automated lines, robots first of all, cannot be guaranteed by any other technology, and even less by man, especially in foundry».

But this fact, the choice of computerization, automation and robotics in particular, at Fonderia Morini has not coincided with a personnel reduction. «Automation, on the contrary, has completed the personnel’s training and has widened their competences. The adoption of innovative technologies, like robots, not only helps us in ranking among the international sector leaders but allows the personnel to learn things never known before and to revise their role in the company as well as, in general, their value on the job market. Operators, not negligible thing, live also better working conditions thanks to automation. A foundry is an environment that can be difficult. Even if at us technology helps us also in granting a high air quality – we have recently installed a new plant for the air – and very good working conditions for our employees, the difficulties of operating in sandy and hot environments persist».

When these operations, however, are carried out by a machine or a robot, everything is better. «Just so. We have fought the crisis believing in our ideas and in people, but especially in technology, in innovation and in the relationships with other companies. We collaborate and we design together with our customers, we put at disposal experiences and competences, like our Cad/Cam design office. This is the way to win in a market tormented by the crisis and globalized, where the use of technology and automation proves to be essential».

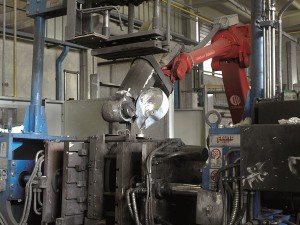

High quality production, constant compliance with standards, precision, rapidity. Issues that with the choice of Comau robot for the chill casting department see their meaning enhanced. Not only words, but facts, as I had the opportunity of documenting by visiting with Luca Morini the specialized department in the branch, still at Cotignola. Entering the factory, Morini explains the robotic isle: «The robot works with 3 different moulds automatically interchanged during the production. This allows us the high speed production of different products and the preservation, like still in our case, of a very high quality standard. Besides, the robot allows us to be flexible, and not only fast, when we produce. This means the possibility of changing setups, moulds and production with rapidity and of satisfying specific emergencies or demands. There is no other foundry technology that would grant it to us».

Morini explains the degree of satisfaction with the robotized technology and Comau. «We have established with Comau a relationship consolidated for years and we decidedly intend, after a first tranche of investments, to pursue that course with other automations to achieve a more and more efficient production».

A happy choice that awards the made in Italy, then. «We are very pleased – says Morini – to award an Italian technology that, by experience and performance, has nothing to envy to international competitors indeed. In the last 5/6 years the world has changed, moving towards the direction that we all expected, certainly not in such a traumatic manner, that’s to say quality, high technology and service. Well, in these so intense and difficult years, to rely on a partner like Comau has helped us in keeping high those quality standards that all recognize and envy to us». A winning choice of a technology that, besides, is already paid back. «Exactly – confirms Morini – the robot that operates in the chill casting department was installed and started about one year ago and, with the deployed performances, we will payback the investment in short time. Not bad at all».