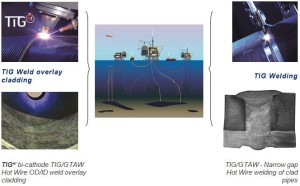

The Polysoude TIGer Cladding System represents the next evolutionary stage in hot wire technology. In addition to the pre-heated filler wire, TIGer incorporates a unique system of two tungsten electrodes in tandem configuration. This allows the ignition of two electrical arcs, which, by way of mutual attraction, combine to convey a single heat source. This single heat source has a lower arc pressure than in classic tandem configurations, yet it is capable of reaching much higher cladding speeds and deposition rates than the standard TIG/GMAW HW process. The exceptional characteristics of the TIGer system mean that it is capable of enhanced process applications in cladding, being ideally suited to horizontal and vertical cladding, both inside and outside components. Its tremendous performance power has been tested and proven. With cladding speeds and deposit rates capable of reaching 950 mm/min with a deposit rate from 2.7 to 5.8 kg/h; conclusive results from adherence checks on cladded layers; indisputable outcomes from intergranular corrosion tests and positive outcomes from chemical analysis.

The Polysoude TIGer Cladding System represents the next evolutionary stage in hot wire technology. In addition to the pre-heated filler wire, TIGer incorporates a unique system of two tungsten electrodes in tandem configuration. This allows the ignition of two electrical arcs, which, by way of mutual attraction, combine to convey a single heat source. This single heat source has a lower arc pressure than in classic tandem configurations, yet it is capable of reaching much higher cladding speeds and deposition rates than the standard TIG/GMAW HW process. The exceptional characteristics of the TIGer system mean that it is capable of enhanced process applications in cladding, being ideally suited to horizontal and vertical cladding, both inside and outside components. Its tremendous performance power has been tested and proven. With cladding speeds and deposit rates capable of reaching 950 mm/min with a deposit rate from 2.7 to 5.8 kg/h; conclusive results from adherence checks on cladded layers; indisputable outcomes from intergranular corrosion tests and positive outcomes from chemical analysis.

Further information: Polysoude