By developing digital holography to become suitable for production, researchers at the Fraunhofer Institute for Physical Measurement Techniques IPM in Freiburg, Germany have been able to detect micro defects during production. Digital holography makes it possible to fully inspect all parts – in a matter of seconds.

With the development of their holographic measurement technology Markus Fratz, Alexander Bertz and Tobias Beckmann (from the left) made it possible to fully inspect all parts in the production cycle in a matter of seconds.

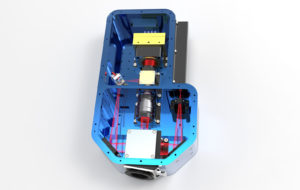

The system can measure centimeter-sized rough objects in fractions of a second with micrometer accuracy – even under disturbances, such as vibrations.

Sometimes every thousandth of a millimeter counts – such as with components for the automotive or aviation industry. In order to determine whether the individual component is fault-free and dimensionally stable, digital holography would be the method of choice. However, this method has so far been slow and sensitive to vibrations. It was therefore not suitable for production environments, and only samples could be tested.

Three researchers from the Fraunhofer IPM – Dr. Markus Fratz, Dr. Alexander Bertz and Dr. Tobias Beckmann – have now brought the process of digital holography out of the laboratory and into the production hall. “We have been able to eliminate all the disadvantages and have therefore, for the first time, developed a system that allows one hundred percent inspection in production,” says Beckmann, who heads the project together with Fratz. “Our system can measure centimeter-sized rough objects in fractions of a second with micrometer accuracy, thereby compensating for disturbances, such as vibrations.” This allows for in-line measurements during the production process for the first time. Instead of taking samples, as before, each individual part can therefore be checked for dimensional accuracy and, at the same time, for the smallest defects. The challenge the three researchers faced was anything but easy to solve. “The search for defects is like trying to measure the shape of a 25-meter-high football stadium from a height of 300 meters so accurately that you can find the footprint of a baby in the grass – and in fractions of a second, even if the stadium is shaken by a light earthquake,” Fratz explains.