Concept Laser showcased new products at Euromold 2014. The centerpiece of the innovations was without doubt the multilaser technology. Concept Laser is comprehensively upgrading its models in order to improve performance.

Concept Laser showcased new products at Euromold 2014. The centerpiece of the innovations was without doubt the multilaser technology. Concept Laser is comprehensively upgrading its models in order to improve performance.

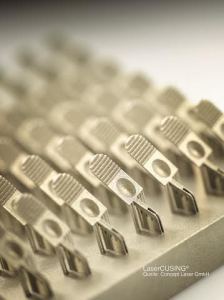

Featuring modern machine design and numerous innovations, the system M2 cusing was presented as a fully integrated laser melting system. Concept Laser has in particular improved the process: here the focus was on innovations in the segmented exposure strategy and on a ground-breaking quality assurance module QMmeltpool 3D. Apart from this, two new certified materials were also presented in Frankfurt.

The new M2 cusing is being brought out with a new, modern appearance. However, in addition to its new look, the machine also has a fully integrated structure, i.e. there are no longer any external components for the laser and filter system. This self-contained solution provides benefits for the user in terms of the accessibility of the system components as well as greatly reduced space requirements. However, it is not just externally that the new machine design underlines the enhancement of the system technology. The new M2 cusing is, for instance, equipped with a new filter design. This has increased the surface area of the filter by a factor of five – from 4 to 20 square meters. The new filter module has been designed with fixed tubing as well as being fully integrated into the system. The frequency with which the filter has to be replaced can be reduced to such an extent that the overall throughput of the system is increased. This enhancement is important when using the multilaser technology. With the increased formation of smoke particles, the new filter further enhances productivity. “Significantly faster build rates demand safer filter replacement concepts. Every filter change must be quick and easy. We have incorporated the new enhanced filter technology with safety as our primary consideration”, explains Dr. Florian Bechmann. For instance, the M2 cusing is fitted as standard with a water-submersible filter in order to guarantee safety when changing the filter.

“Our product range is now enhanced with multilaser technology and it directly affects the exposure time. Our experience has shown that build rates can be increased by up to 80%. That’s a very pleasing result”, notes Dr. Florian Bechmann, Head of Development at Concept Laser. The multilaser technology is initially being incorporated into the medium size segment. For instance, a multilaser version of the new M2 cusing – called the M2 cusing Multilaser – is available right now. It’s available with 2 x 200 watt lasers, or alternatively with 2 x 400 watt lasers. What’s more, Concept Laser has also signalled the arrival of multilaser technology in their largest machine, the X line 1000R. In addition to the X line 1000R which is already well established in the market, in the near future the X line 2000R will also be available, and will be fitted with 2 x 1000 watt lasers. The aim is to drive ever faster construction speeds which are required by users in the aerospace and automotive industries.

Concept Laser has likewise raised its game in relation to its exposure strategy. The key term is segmented exposure. It is common that higher laser power produces a rougher surface finish. “Our new systems technology implements the hull-core principle, which enables density and surface quality to be controlled independently”, says Dr. Florian Bechmann. This means that segmented exposure has an influence on the outer parts of the component – including overhangs and high-density areas of components – in a targeted manner. “An optimised exposure strategy improves both the level of quality and build speeds.” The end result is that a component’s performance characteristics can be significantly improved through the use of segmented exposure strategy.

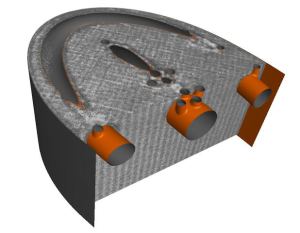

Concept Laser has demonstrated key enhancements in real-time process monitoring for quality assurance purposes. “Inline process monitoring” is one of Concept Laser’s strategic technology fields, and one which we are now expanding with the QMmeltpool 3D”, says Dr. Florian Bechmann: “If we can dynamically micro-analyse the construction process, the level of quality increases. Important key industries with their sophisticated applications have enabled us to develop this important innovative step”, Dr. Bechmann continues. In a comparable manner to computed tomography (CT), the new QMmeltpool 3D makes it possible to generate 3D data sets that corelate directly to the component and/or it´s structure. According to Concept Laser, this allows local effects that arise during the construction of the component to be clearly identified and analysed. The practical added value of this innovation is not just that it is an original way of providing real time quality assurance, but also that production builds can be optimised through iterative variation of the parameters. Support structures can be adapted, and above all, the construction of the component can be structured in a more efficient and production-friendly manner. And not least, real time monitoring opens new opportunities in the materials research field.

Concept Laser’s development center has certified two new materials, both of which premiered in Frankfurt. For high-temperature applications, Inconel 625 is now available. This material is mainly intended for use in turbine construction where components are exposed to high thermal stress of up to 1000°C. The second material is the stainless steel, 17-4 PH. This material can be hardened and consequently made highly resistant to abrasion, wear and corrosion. These properties are attractive above all in relation to medical instruments. The certification of 17-4 PH stainless steel applies to the Mlab cusing R, M1cusing, and the M2 cusing series.