Blechexpo – the international trade fair for the sheet metal working – confirms what it already let us forebode at the end of the last edition: for the first time, in november of the current year it will take up all the halls of the exhibition fairgrounds in stuttgart and therefore it will be bigger than ever!

While in 2015 Blechexpo could count 1,234 exhibitors from 36 Countries and a gross exhibition surface of 90,000 m², in 2017 it will exceed 1,300 exhibitors from about 40 nations and will cover 105,000 m² (area: +15%). If we add the internationality rise, Blechexpo consolidates its ranking of second international trade fair but it is the first in the year when it is held! Together with Schweisstec – International trade fair for joining technology – if offers a complete and competent survey of the process chain of sheet metal, pipe section and profile working.

Sheet metal – pipes – profiles

Along with pipes and profiles, sheet metal has evolved into a more and more important construction material, to the extent of representing today a valid alternative to cast iron, steel and plastic materials. The world of vehicle, machinery and equipment manufacturing does not use any longer massive welded steel constructions or plastic parts that integrate several functions and are therefore very expensive, but it prefers modular, lightweight and FEM-optimized components. Blechexpo’s nomenclature includes all useful products and services (sheet metal processing machines, cutting and forming technology, pipe and profile processing technology, joining and fastening solutions and semi-finished products) for the economic sheet metal, pipe and profile processing, and thus it serves as a guideline for practical stand-alone and system solutions.

Sheet Metal Industry 4.0

In a world where Industry 4.0 is an increasingly popular topic, companies operating in the sheet metal, pipe and profile processing and their suppliers easily comply with it, since computerized technologies have been a reality in this sector for a long time and find broad applications, from CAD/CAM used in each working phase to the data transfer, from programming to the quality assurance. The same applies for the automated handling of raw materials and finished parts, for automated storage systems, the machine loading according to the acquired orders, the handling of blanks at presses and the positioning of welding robots in production in flexible quantities.

Added-value trade fair

The new hall layout allows optimizing the occupancy structure according to the specific fields of technology. In the halls 1, 3 and 5 are on show machines, tools and peripherals for the sheet metal working. Halls 7 and 9 are dedicated to the complex blanking issue. The hall 4 is focused on the pipe and profile processing and the hall 8 on presses. The hall 6 hosts instead Schweisstec with the joining technology. This results in a higher orientation to the process chain, which represents a notable added-value for both exhibitors and visitors and gives rise, for instance, to targeted technological presentations and to an approach among single technologies: cutting and forming, surface levelling and cleaning treatments, assembling and joining. Concerning this, the synergy with Schweisstec becomes particularly strong, as the latter deals with the thermal and mechanical techniques and processes for joining, assembling and welding, and therefore it perfectly completes the process chain that ranges from the production of sheet metal parts, pipes and profiles up to the implementation of components and equipment. The subdivision according to key issues is a further advantage for visitors, who can then concentrate on the sectors of their interest in targeted and rational manner to decide purchases and investments.

New DALCOS LXN1500, a laser cutting system with patented vision system

The new-born DALCOS LXN 1500 is the latest update in laser cutting field. The system has a larger working area that makes the production more efficient, fast and flexible. LXN 1500, like all Dalcos laser systems, is equipped with the Dalcos vision system increasing the precision and flexibility of the production.

Dallan exclusive vision system Laservision received the official patent certification the last June and uses a high-resolution camera that identifies both the strip/panel edges and the pre-cut holes. The way it works is extremely simple for the operator and the algorithm developed by Dallan software engineers takes care of the measuring and calibrating.

This exclusive system, available in all Dalcos LXN and ELXN laser cutting systems, ensures high performance, high precision produced parts, high flexibility processing and several advantages:

1. Processing long parts up to 14 m length

2.Processing from coils and from pre-cut sheets

3. Working without any side guide and extremely fast setup

4. Working with coils from the steel mill

5. Processing of pre-punched panels

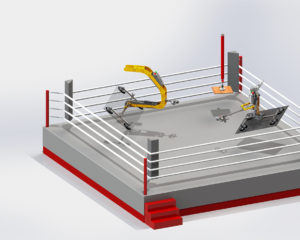

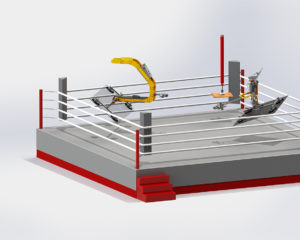

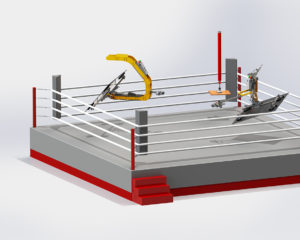

A new 180° turner eT-Hover-loop in the Eurotech lifter series

At Blechexpo 2017 Eurotech will present the highlights of its catalogue to a professional audience. This year, the multi-talented eT-Hover-allround lifting device and the 180° turner eT-Hover-loop will be joined in the ring by the eT-Lift-mini, a compact version of the Eurotech tube lifter series with a pistol grip.

The modular eT-Hover-allround is a compact, versatile tool, the base unit of which can be converted individually and flexibly to fulfil a wide range of handling tasks. This true multi-talent allows horizontal and vertical lifting, pivoting and rotating through 360°, as well as combinations of these movements. Vacuum-sealed loads such as metal sheets, glass panes or plastic or wood panels can be handled in many different ways. Depending on the vacuum components and vacuum generators used, these lifting devices can handle loads weighing up to 500 kg. The eT-Hover-allround is equipped with four suction cups that can be moved along the cross beams. Additional suction cups can be added depending on the task at hand. Their size and order is based on the type and size of the objects to be handled. The expandable, ergonomically designed control panel combines all necessary functions: suction, aeration, crane up/down, turning and pivoting. The control unit is equipped with a blow-off function to ensure safe detachment of the load. The eT-Hover-allround is fitted with a 2-circuit system and is also available as a battery-powered device suitable for construction sites.

A new champion in the ring, the 180° turner eT-Hover-loop will be competing for the first time this year. This lifting device turns flat, vacuum-sealed loads of different materials around 180°. Using a linear actuator, it can turn panels weighing up to 500 kg. This device, too, is equipped with an ergonomic operating handle, allowing the user to control all functions intuitively.

While the eT-Lift-mini operates in a lower weight class, it is just as useful as its brawnier colleagues. Repeated bending over, lifting and moving of even light to medium-weight loads can lead to back problems: the eT-Lift-mini prevents such injuries. It is a small, compact tube lifter with a pistol grip. The pick-and-place device suitable for frequently recurring work processes can handle loads such as furniture parts, sheet material, cardboard boxes and other packaging weighing between 20 and 65 kg.

IMCAR presents 3 rolls 3RHT model with variable geometry

IMCAR will exhibit the 3 rolls 3RHT model with variable geometry able to bend metal sheets from 10mm up to 200mm thickness.

Accuracy, speed and high performance of bending (both in pre-bending and bending) make the 3RHT a unique machine, especially when working thick materials.

The 2 side rolls (with their horizontal movement) and the upper one (with its vertical movement) can move independently to obtain the best results.

The main advantages are: possibility of bending a wide range of thicknesses and materials, adjusting the geometry thanks to the independent movement of the 3 rolls; the sheet is always in horizontal position, even during the process of pre-bending, preventing the sheet from slipping or tipping over; possibility of quick replace of the upper roll; savings on foundations, in fact working in horizontal with lateral rolls, the working height can be reduced; PLC + control desk for easy control of all movements; alarms and immediate stop device in case of emergency and braking system with moving heads to always ensure 100% of braking.

More fabricating solutions from Mate precision tooling

At Blechexpo 2017 Mate will show more fabricating solutions, including its new Thick Turret metric QCT™ Quick Change Tooling for A and B stations, new MPM82 material for Thick Turret A and B station dies and more…

Mate patent pending QCT insert style punching system is now available in metric (long stem) versions for thick turret A and B stations. The QCT system is simple and intuitive to setup. Simply flip the durable latch to remove and snap the new insert into place. Original Style QCT is fully compatible with Mate’s Ultra® family of guides and canisters, and Mate’s Original Style guides, spring packs and Rapidset™ canisters. These punches are fully interchangeable with Amada NCT, NEX and Z-Tooling systems, as well as Wilson Thick Turret Metric punches. Mate QCT punch inserts are made from M4PM™ tool steel, durable and lasting tool steel. Punch drivers are coated with SuperMax™, Mate’s next generation coating to minimize wear and preserve fits.

Another nice feature – only one punch driver is needed for rounds or shapes. Mate’s Thick Turret A and B station dies have superior performance and longevity with the new optional MPM82 tool steel. Designed for use in high performance tooling applications, Mate’s MPM82 is a high speed, particle metallurgy steel designed to provide high value and exceptional versatility. Ideal for the most demanding punching applications providing higher quality parts and lower cost.

Also see Mate’s broad line of Trumpf style tooling in Original Style, Quicklock™ and Next™ versions designed for every fabrication application.

NewStark, tailor-made production for bending units roll

ROLL units are devices that allow simultaneous calibration and bending of metal sheet or steel.

In comparison with standard punch/matrix solutions, operators can extraordinarily reduce both the number of progressive die steps and the tonnage requested for bending.

Many kinds of bending can be produced with these rotary benders, such as undersquare folds (with an angulation less than 90°), open folds (greater than 90°) and with large radius, always maintaining the requested tolerance.

Also performs «Z» open folds, doublefold ecc.

The system consists of a rotating previously shaped according to required applications. The product is built with very strong materials, wear and compression resistant, hardened and surface treated in order to considerably reduce friction.

According to different fixing system, three different models can be chosen: each model can vary depending on the type of material, thickness, geometry, bending radius and length.

Since several applications are to be found, NewStark decided to provide its customers with tailor-made products.

The final user, after having elaborated the 3D file with NewStark technical office, confirm it, allowing the production team to start the project.

Ready for series production

This Omt die is a combined progressive-transfer tool, that simultaneously produces 2 pieces for automotive industry (RH piece and 1 LH piece).

Starting from coil width 510 mm, the die performs the first 10 steps with progressive die: 3 steps for blank cutting, 1 step for forming of recesses, 1 step for hole cutting, 5 steps for piece bending.

The last step, made with transfer system, performs the final closure of the piece.

The evacuation of the pieces is made laterally in the die, using specific pneumatic cylinders. The extracted pieces end up on conveyor belts, that carry the pieces directly to the mounting line.

The dimensions of the die are 3500x1500xH750mm.

The production of the piece is done on transfer press 1200 Ton.

The project of the die has been made with CAD 3D supported by dedicated application for the development of sheet metal.

Bending punches and matrixes are made with Toolox 33 with relative coatings, cutting punches and matrixes are made with hardened 1.2379.

All structures are made with 1.0503. The progressive die and the transfer die are installed on a single upper and lower union plate for the fixing of the die on the press with the help of fast clampings.

All the parts that build the die are made with machining centers and cutting edge EDM facilities, supported by CAM 3D programming. The samples produced with the die have been controlled and measured with 3D measuring machine.

The die has been delivered to the customer already tried out and ready for series production.

World premiere by Prima Power

Many new technologies and solutions by Prima Power have their world premiere at the Blechexpo. Prima Power products are presented under the slogan «Prima is Power»: always more productive, flexible and connected, Prima Power laser and sheet metal machines are a boost of power to companies’ business and competitiveness.

Visitors of Prima Power booth will gain a first-hand preview of the group’s latest innovations. The exhibits cover all technologies and are Industry 4.0 ready, as the entire Prima Power product portfolio.

The top-of -the-range 2D laser cutting machine Laser Genius 1530 with Combo Tower Laser automation system is showcased for the first time with a 10 kW fiber laser source by IPG Photonics, which further boosts its performance, especially on high thicknesses.

For the first time at an exhibition, Prima Power showcases its LPBB (Laser cutting -Punching – Buffering – Bending) manufacturing line. It features fiber laser cutting, punching and automatic bending enhanced with LSR loading and stacking robot. As world premiere, also a new generation laser marker is introduced, integrated into the productionline.

The eP-1030, the most versatile servo electric press brake of the eP family is now available with the new version of the bending follower option, allowing the simpler and faster positioning of big and heavy parts.

A Software area is dedicated to live demonstrations and presentations of the full array of products for digital manufacturing.

Automatic RIVIT feeders for more productivity and higher safety

The reduction in the riveting time is an essential goal for the industrial activity. This is why Rivit projected a pneumatic/electric unit, that loads the rivet or the rivet nut directly on the head of the riveting tool: its use halves the installation time and eliminates, in the loading phase, the contact between the operator’s hand and the body of the fasteners, assuring more productivity and higher safety.

RIV606 is an automatic feeder for standard blind rivets from d.2.4 to d.6.4 mm and it can be used with tools with mandrel suction, such as models RIV502/RIV503/RIV504/RIV505.

RIV616 is an automatic feeder for rivet nuts from M3 to M8 with cylindrical or hexagonal shank, with dome, reduced or countersunk head. RIV616 can be used with tools as RIV938, RIV939 and RIV941 model.

TECHNICAL DATA RIV606

Dimensions (width x depth x height): 340×530/630×300 mm

Voltage: 220 V 50 Hz

Installed power: 100 W

Air pressure: 2/4 bar

Weight: 34 Kg

TECHNICAL DATA RIV616

Dimensions (width x depth x height): 340x530x300 mm

Voltage: 220 V 50 Hz

Air pressure: 2/4 bar

Weight: 32 Kg