We illustrate an alternative way to the casting repair

Enrico flamigni, SCM Fonderie – Filippo mazzon, F.lli Mazzon

The foundry has processes that are determined by numerous variables whose perfect control sometimes is not completely feasible and therefore the possibility of executing correct repairs, especially when defects emerge after mechanical operations, can permit to avoid the burdensome reject costs. An additional reason for researching possible solutions to the repairable defects is also the very frequent impossibility of solving the defect immediately and definitively, with evident consequences also on delivery terms and heavy impacts on production lines. The repair, however, must remain an exceptional solution, always agreed with customers, even better if before the job order acquisition, with technical specifications reporting the various casting zones with specification of the types and degrees of the defect acceptability. We are obviously referring to those foreseeable by the common experience for the type of produced casting, according to the casting application.

A new possibility to solve tightness issues in castings is represented by an innovative repair way of the same, particularly suitable for medium-big size ones.

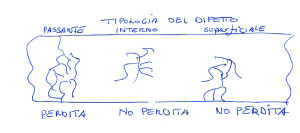

In general, tightness problems are generated by porosities or sand inclusions that feature a morphology able to put in communication the external surface with the internal one of the casting, (fig.1) creating the loss of oil, gas tightness and so on …

It is advisable to test the castings intended for those applications with penetrating liquids at the rough state and then, later on, after machining, to test them with apposite gas pressure equipment to control their tightness before the assembly. Tightness problems can therefore be detected both in the internal testing phase and after the machining by the customer or the subcontractor.

When the part repair through impregnation is possible, after preventive agreement with the customer, the way generally followed consists in the treatment with organic pressure fillers, or in vacuum in autoclave, or with apposite equipment that allows pressurizing the part under treatment.

The common way, then, is to use organic fillers, generally resins, which through the pressure application fill the internal porosities of the material and solidifying grant their tightness in the majority of applications. This way of proceeding is also used to treat in serial way the produced castings, without a preventive testing to assure the absence of losses in the use.

The use of inorganic fillers of the silicate class is commonly adopted.

A new modality that is taking hold on the market and allows a simple but effective application consists in the use of purposely modified sealing products that penetrate into the porosities exploiting the capillarity phenomenon.

There are on the market resin-based organic products that permit the local treatment and, in other words, of the only casting zone affected by the loss phenomenon. We can easily apply these products by brush or spray or by immersion, in case of small-size castings.

In this sector, they have recently developed a new sealing product with active capillarity, with inorganic base in aqueous medium, with the commercial name DEEPcasting, able to match the efficacy and the safety of the treatment with the environment protection.

Those sealants grant a very user-friendly use in foundry and assure a good tightness result, in all situations. As always, the result and the efficacy of the treatment must be assessed trough leakage test, if the treatment is not resolving, it can be repeated, as it happens for standard impregnation processes.

The latter solution is suitable for medium-big size castings, where the treatment with vacuum or pressure method requires the implementation of very expensive equipment, in addition to an often demanding work. Sometimes emerge situations in which, with the standard technique, it is necessary to carry out an extended impregnation, even if the loss is localized in a small spot; in this case, the product that acts by capillarity can represent the optimal solution, turning out to be the most suitable for the treatment limited to the only zone concerned by the leakage, it avoids in fact the extension of the application also to the remaining part of the casting that does not show any problem.

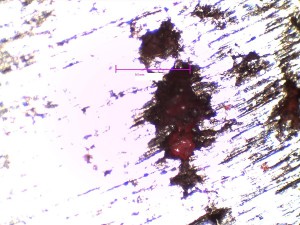

Some macrographs (Fig.2 and Fig.3) show the product solidified inside the porosities with sizes under the millimetre, the substance has been opportunely coloured to be highlighted, while it generally features transparent colour and amorphous aspect. The inorganic sealant used is highly suitable when a notable resistance to chemical agents and solvents is requested, where instead the use of resins can represent a problem because they can soften or melt, or even be chemically destroyed.

Conclusions

The demand for castings with more and more challenging characteristics, complex geometries and thin sections, for applications where a perfect fluid-or gas tightness is needed, for instance in hydraulic applications, in motors, in air and technical gas compressors, has determined the appearance of tightness problems. The solution of the problem by vacuum or pressure impregnation has been known and applied for a long time, while the local application, that is to say only on the defective zone, with a product that penetrates by capillarity and gravity, can constitute a further helpful tool at disposal for solving this type of problems, especially in medium-big size castings.