Several are the opinions about the Additive Manufacturing: Mauro Varetti from Avio Aero explains his vision

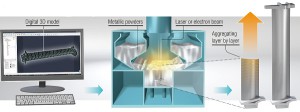

The Additive Manufacturing has revolutionized the standard production chain, modifying the concept of production process and of design of the manufactured good.

Mauro Varetti, engineer at Avio Aero, in the course of his professional career has had the opportunity of developing his competences in manufacturing ambit for the aerospace industry up to reviewing, around 2008, foundry and the possible ways of conceiving it.

Mr Varetti, you have defined the Additive Manufacturing as the new foundry: why?

In the aerospace sector, to keep pace with times, foundry must be transformed. Already in 2011 we got in touch with the Additive Manufacturing to make wax models, without making use of “tooling”, and for the casting of some sand components, without turning to forming. We might state that our knowledge of the technology was indirect: in additive we implemented sacrificial elements then used in the standard foundry process.

Nowadays an alloy widely used in the aerospace sector is TiAl and at Avio Aero, since the early 2000s, we had carried out various studies concerning the blades of the last two stages of low-pressure turbines. In Additive we started making the sprues connected with the blade geometry: unfortunately TiAl does not like the casting process! Therefore, our experience starts from foundry or, better, from what is traditionally a foundry product. Just for this reason, we started wondering whether the additive technology could allow us to eliminate the construction of sacrificial elements, directly achieving the finished piece. The technology seemed very promising and the tests carried out, also in collaboration with Universities and research bodies, confirmed it: the Additive Manufacturing can succeed in what foundry cannot manage. For this reason, I think that Additive can represent the new frontier, the foundry evolution.

Starting from the experiences by now consolidated at Avio Aero, what is the state of the art of the additive technology?

On new aeronautical engines, the preferred choice to produce TiAl blades is the EBM technology, that is to say that additive technology that exploits the electron beam for melting.

Our studies and the tests about the possible applications of the Additive Manufacturing have let us discover a new and fascinating world, with not well defined boundaries, yet. We deem Additive as an enabling technology, able to solve several problems and, besides, permitting us to enter a very promising and exclusive market, which boosts us to develop our knowledge constantly.

There is much talk about the authorizations for the use of additive manufactured products in flight …

Nowadays Avio Aero parts fly! The core of the matter is to understand what must be certified: the productive process or the piece conformity? Federal Aviation certifies the part compliance with the “design intent”. In the blade case, to the ends of the flight safety, it is essentially necessary to evaluate the resistance to “creep” and to vibrations, especially in case of low cycle fatigue. Concerning the material, well, today the TiAl is a renowned material, and known are the relative curves, both in case of casting and now of EBM: the additive manufacturing must prove the material consistency in metallurgic terms and tests must prove the conformity. The real requirement is to make a plane fly according to the performances demanded: productive methods are not therefore the issue of aero-navigability certification but they must prove to be controlled to grant the constant part quality.

What about materials?

Let us start from an assumption: we must never forget the industrial point of view. Apart from that, not all manufactured goods can be conveniently produced with additive technology and we should opportunely evaluate the productivity, meant as energy spent in time, and the sizes both of the component and of the batch. Concerning materials, all lost-wax or sand ones used in foundry can be successfully exploited in Additive Manufacturing processes. Aluminium alloys, for instance, are very used, also Al 357, which contains slightly less than 1% of Magnesium. The Additive Manufacturing can “replicate” foundry, but a material developed for foundry has determinate specifications because it must be cast, but if the casting problem disappears, why should we add additives favouring it? Starting from this assumption, we are devising new alloys that lead also to the study of the production systems of the related powders. Still speaking of materials, the Additive is already quite consolidated on Nickel-based materials, CoCr alloys, which have been one of the first materials used, essentially because they were well-known and widely available in the sector of dental implants. The additive technology starts from the availability of powders, which must be produced according to specifications suitable for use for a determinate additive technology; therefore, we cannot take it for granted that powders conceived to be used on EBM machines can be used on DMLM machines, too, and vice versa; also the powder productive process must be controlled as the Additive process: even minimal variations of the chemical composition can have relevant impacts on the finished product metallurgy.

Avio Aero is a business of GE Aviation and it is the excellence centre for the whole General Electric Group in the field of mechanical transmissions and of low-pressure turbines and, for the whole GE Group, TiAl treated with EBM technique is the first choice and, proudly, I underline that design and production are carried out in Italy. Today, moreover, the aeronautical Avio Aero components already fly.

A strange concept, underlined by someone: back to the city…

The Additive Manufacturing can make lots of things and it is considered an extremely “portable” technology thanks to the very low energy consumptions. The concept of back to the city recalls the broader one of smart city, which sees the return of companies to cities and therefore, for instance, we go to work by bike instead of by car or commuting. Obviously, companies can go back to the cities if they satisfy some determinate requisites, including the energy consumption and the environmental sustainability. The additive technology meets the requisites and then it can be defined back to the city.

What future do you foresee, then, for the additive technology?

In the next future, I think that at least 20% of aerospace components will be produced with additive technology, expressing an estimate in a value context. It is anyway fundamental to change our mentality completely. We talk a lot of Think Additive, but what does it really mean? We commonly think that only the design modality must change, oriented to the product optimization according to the use, but the Think Additive goes far beyond, becoming a cultural question: the way of producing changes and then also the managerial aspect must change. Upstream, obviously, we must always remember that this technology is not conceived and developed to replicate existing parts, sometimes fruit of a technology more focused on the productive technology than on the mechanical specifications that the component must have. I deem the Additive a marvellous technology, but not for all: today it can be proposed to the right market and to the right customer. We can implement excellent prototypes and small mass-productions; nevertheless, for the most important series, the current machines are not competitive, yet, and then it is necessary to work to improve the recurring product cost. More performing machines, for instance, with bigger power or lower number of strokes, can further enhance the competitiveness in comparison with foundry.

Have you got a message to think over?

Yes, even if it may seem debatable. The Additive Manufacturing has already demonstrated so many unquestionable advantages compared to conventional techniques, I do not know to what extent transposed, that already today we might exploit them successfully to create consent and reliability, to finance successively further developments however simply aimed at understanding what additive technology and what machine is the best. This does not mean to deny the need of evolution and innovation but instead to exploit better what the evolution and the innovation of the past have “given” us today.

Therefore, we should focus on what we already have and know: let us consolidate it, and then let us progress. “Too much” can make us waste resources, losing effectiveness.