Optimizing the machining cycle? A valid support comes from tooling and, in particular, from the vices of the Gerardi multitasking range allowing the piece machining on the five sides.

Optimizing the cycle matches the production optimization, focus of attentive studies and evaluations in a time of strong competitiveness. A valid support comes from Multitasking vices, developed by Gerardi SpA, headquartered at Lonate Pozzolo (VA), company that has been for years a renowned protagonist on the world stage of tooling systems for machine tools.

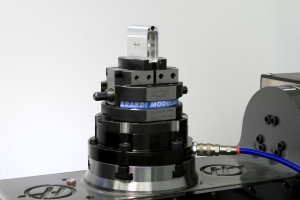

The range of Multitasking vices is specifically conceived for 5-axis machining centres, permitting to intervene on the five sides of the workpiece with precise references, in small spaces and granting null wears and high stiffness. Thanks to their compact design, these vices suit all 5-axis machining centres at best; the machined base is prearranged for spacers, it facilitates the eventual lift on fixed spacers or on ZERO POINTS.

The excellent reasons…

Multitasking vices are designed with very precise features and each of them implies a precise advantage for the user, in compliance with a quality/price ratio. The use of high-strength normalized, hardened and tempered steel (hardness 60±2HRC) allows achieving null wear, endless service life and higher workholding safety.

The high machining precision, the grinding of sliding plans, of jaws, of slides and of the rack system equipping the slides themselves grant the interchangeability and the perfect alignment with all the components of the system, as well as the positioning repeatability within 0.02mm.

The solid and compact structure allows minimal overall dimensions and, in general, great equipment handiness.

The wide range of solutions, coupled with the modularity, permits to attain an almost unlimited workholding range, with highly customized combinations and compositions, starting, however, from standard items. The base with longitudinal and transversal keys and a centring pin grants minimum set up times, with perfect alignments and/or couplings of more vices with the machine axes. The threaded holes of the jaws allow the fixing of extension elements or of stackable jaws, for special executions.

When the vice can make the difference

All the vices and the accessories by Gerardi are modular elements, interchangeable and perfectly aligned one another in order to achieve different clamping solutions. According to that principle, the only element that differentiates the equipment with identical width is the base, whose length determines the maximum vice opening, while the other components remain unchanged. Simply adding or replacing some accessories it is then possible to vary the clampingtypology, consistently with the specific requirements.

The base concept is the interchangeability of all the elements composing the equipment, with the certain possible use of more vices on the same machine, with perfect positioning and alignment in few seconds. This is enabled by the high precision degree of the vice itself, with particular focus on the base height, the alignment with longitudinal slot small blocks as to the fixed jaw, the verticality of the fixed jaw as to the base and the parallelism of the base plans. Such features allow solving even the most complex clamping problems in few instants and with the use of several vices.

The Multitasking range is expressly devised for 5-axis machining centres and allows optimizing the machining cycle at best.

Thanks to the possibility of machining the workpiece on five sides, it is possible to execute most of the required processes with a single setup, granting higher precision, the cycle optimization and also a minor waste of material, to full benefit of production costs.

Multitasking vices used on 5-axis machining centres, to allow the accessibility of the machine spindle to the 5 sides of the part, must sometimes be raised by using spacers

Spacers can be of standard type or equipped with ZERO-POINT system.

The use of fixed spacers implies the removal or the positioning of the piece in the vice that remains screwed to the spacer with consequent operator access to the machining area.

The use of spacers with ZERO-POINT device allows the removal and the positioning of the vice itself from the machining area, enabling the operator to position the piece in the vice on machine board during idle times or the machining of the previous component, further reducing machine downtimes.

Either self-centring or eccentric, a wide range of standard and customized jaws is available also for MULTITASKING vices.

The jaw plays an essential role as well

If the target is the minimization of production costs, by optimizing cycles, this is enabled by the use of GRIP jaws that, having a profile equipped with special toothing, allow high-pressure clamping, ideal also for roughing and heavy stock removals. The special tooth profile of GRIP jaws has a high material penetration efficacy, with consequent immediate clamping action: in this way, it is possible to reduce the forces that act on the piece with significant precision improvement.

GRIP jaws on Gerardi Multitasking vices allow then:

Improving the machining precision thanks to the reduction of the applied force, which results in minor bends or deformations

Increasing the specific pressure, with evident higher clamping safety and lower material waste (only 4 mm of stock)

Accessibility of the piece on 5 sides, with cycle time saving and higher precision.

The company

The activity of Gerardi SpA starts in the early Seventies as mechanical workshop for subcontracting machining but, in the lapse of few years, it turns to the marketing of guides and rolls in-house designed and manufactured, soon standing out as first absolute enterprise proposing modular precision vices for machine tools. Today Gerardi designs and implements innovative solutions in the field of the workholding of parts made of steel, cast iron, aluminium and so on, which need milling, drilling, threading, grinding, EDM and/or control operations.

Multitasking vices in short

Multitasking vices by Gerardi are summarized in 6 points:

- Null wear

- Clamping rapidity

- Modularity and versatility

- Precisions ± 0.02 mm

- Rigidity and safety

- Compact design and great handiness