Gnutti Carlo and Vimacchine, two Italian excellences of international relevance

Gnutti Carlo is specialized in the production of high-power engine components and it is an OEM for the outstanding brands in the marine, earth handling, agricultural, truck, generating set and motorcycle industry. Two are the winning choices that have characterized this Group, leading it to be a player relying on a turnover of over 400 billion € and 2200 employees: technological development and diversification.

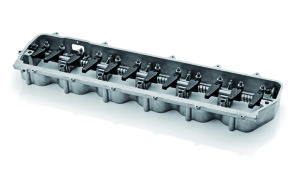

Today Gnutti Carlo is a leader reality in the production of rocker arm assemblies and components of injection systems for medium-big power engines intended for multinationals of important sectors.

From its headquarters at Maclodio (BS) Gnutti family, reached the fourth generation, manages the entire Group composed by 12 productive sites, 2 sales offices and 3 research and development centres located in 9 Countries.

Besides innovation, diversification is the other relevant factor for the Group.

Paolo Groff, CEO of Gnutti Group, explains: «Investing in research and development has always been, for us, a winning strategy, as well as the will of exploring new courses keeping us competitive on the market: our two last takeovers perfectly conform to this strategy. The first, in particular, Ljunghäll Group (two factories in Sweden and Czech Republic), was a strategic operation because the business operates in the aluminium die-casting sector, becoming for us a new and synergistic intervention field, with the possibility of managing in-house the entire value chain. The takeover of Vici Industri AB was vice versa aimed at growing, to strengthen our position in the market of diesel engines for commercial vehicles, thanks to an increase of customer portfolio and productive capacity».

The “local to local” logic

The international growth of Gnutti Carlo started in 2001 with the takeovers of Kendan Exeter in Canada, followed by Finnveden Powertrain in Sweden in 2007 and by WH Industries (Welles) in the United States in 2012. The incorporation of these two enterprises resulted in new customers, new plants and a great technological enrichment.

In our growth process, the choice consisted in managing big multinationals’ job orders according to the “local to local” logic, which allows a better management because currency risks notably decrease while maintaining the entire value chain inside the same macro-region. Mr Groff adds: «To satisfy global customers we must be global suppliers and be present in all productive areas where our customers are present. In a short lapse of time, we had then to equip our subsidiaries with suitable plants for machining operations, in particular the Chinese and Indian branches that some years ago were in an initial development phase. Then we analysed and defined industrial processes here, in our head office, and afterwards we looked for a technological partner able to transfer everything in the two Countries, doubling or tripling the production chain». After a very accurate evaluation, the choice fell on Vimacchine. In 2012 started a fruitful collaboration, began with the supply of the first six machines by the Indian factory at Ranipet.

«Since the beginning of this collaboration we have bought and installed forty horizontal lathes and horizontal and vertical machining centres by Hyundai, the majority of them with automatic pallet changer, including F600D and HS6300, for Canada, F410D, F500D and L210 for China, F500-50 and F500D for the Indian subsidiary as well as some models of F500D, L210A, HS6300 and L210A for the Italian market – explained Giampaolo Santin, Vimacchine General Manager- All machines are intended for the machining of lifters, shafts, valve bridges and rockers arms, in a notable dimensional range (from 200 grams up to 30 kilograms of weight and with sizes ranging from 100 millimetres to more than one metre)».

A consolidated method

In order to standardize processes and procedures for the entire Group, in all departments Gnutti Carlo has recently introduced the LEAN Manufacturing with a dedicated team managed by a Kaizen Promotion Director.

The quality logic is structured at corporate level, too, with a single manual and a single system, in force for all production sites, run by Brescia headquarters that take care of organizing audits in all factories, for an assessment of the correct procedure applicability. «Department technicians are entrusted with the verifications of the incoming materials, with the process control and the selection/verification of suppliers, as well as of final tests, before delivering the finished product, in full conformity with ISO/TS 16949:2009 – added Mr Paolo Groff – The logistic sector refers instead to single productive units because, adopting the local to local logic, a centralized system is not necessary». Fundamental importance holds, by Gnutti Carlo, the aspect of the personnel training, constantly updated to keep pace with the most cutting-edge production and design techniques.

This logic of excellence in training highlights the proximity between Gnutti Carlo and Vimacchine that, through training courses delivered directly on the spot, allows the operators of the Brescia company to exploit the characteristics of machining centres at best. This added value completes the service package supplied by the Vicenza company, which ranges from the start-up to the technical and maintenance service, to allow Gnutti Group to produce, successfully, in each of its factories spread all over the world.

About Vimacchine

Thanks to the know-how gained in several years of activity, Vimacchine can support companies in the choice of the right plant for machining processes and the factory automation. Concerning this, Vimacchine represents a real global partner for its customers in Italy and worldwide. Fundamental the collaboration with prestigious brands like Hyundai Wia, Dah Lih, Hedelius, Shuster, Fuji, Unisign, Hankook, Enshu, Skoda, Aba-Elb, Frog and the controlled Proteo.The One Global Supplier option represents in fact Vimacchine’s capability of analysing productive processes, designing and implementing automated production systems in Italy and afterwards installing them worldwide. This skill springs from the deep machining knowledge, from the machine automation modalities and from the sale agreements signed with producers.