On the markets since the end of the nineties, the brescia upt, with headquarters at Desenzano del Garda, has always marketed tools and special devices for the sheet metal working in our country and has constantly widened its offer range in time.

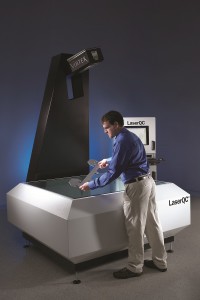

Established in 1997 at Desenzano del Garda (Brescia) where it still has its headquarters, UPT is a company specialized in the distribution on the Italian territory of primary brands on a world scale in the sector of the production of sheet metal working tools. Among them: Mate, Tecnostamp and Wila, without forgetting other protagonists of its portfolio of the relevance of Rolla-V and of Wing Bend. Among the reasons for its success, the company undoubtedly highlights the creation of a professional sale network, able to offer complete consulting services together with a skilled after sale service. Likewise, also the range of products and brands that the company represents in Italy is selected with utmost attention. Characterized by a strong bent for customer service and by the constant research of innovative solutions, UPT stands out also for the active collaboration that it can propose to customers in the ambits of the design and of the implementation of prototypes that aim at satisfying and realizing whatever customer need supplying, in addition to the distributed brands, dies for presses and special equipment as well as blades for shears, for notching machines, camber tables and other solutions suitable for a multiplicity of operations. Among the new entries inside its catalogue, it is worth highlighting the one, dating back to January of last year by Virtek LaserQC, a fully automated system dedicated to the contactless probing of pieces, characterized by high precision and repeatability. As we have already reminded, the range of solutions at disposal of the Desenzano dealer is various and its description can ideally start from punching products.

From punching to bending

Among them, stands out the name of the vendor Mate Precision Tooling, ranking in the highest international positions in the survey of the production of original tools and spare tools intended for CNC punching machines. The company has its origins in Minneapolis where it started its activities in 1962 and has specialized in the supply both to final customers and to the segment of Original equipment manufacturer, the producers of original parts renowned with the acronym of OEM. They turn to the know-how of Mate in virtue of the numerous innovations made to a wide range of products: from punch and die holders up to multi-tools, tools for index stations, tools for special shears, knockouts, ventilation wings, multiple shears and coining systems, just to mention some examples. Mate offers therefore a range of complete solutions for NC punching machines like Amada, Euromac, Finn-Power, Murata Wiedemann Trumpf, Salvagnini, LVD, Strippit, Nisshimbo, Produtech, Dalcos, Rainer, Danobat. Today UPT stands out as one of the major distributors on a world scale of the United States company. As far as bending products are concerned, the offer by the Lombard UPT is characterized by the presence of Wila and Tecnostamp brands. Setup in 1932, Wila has patented an innovative system of rapid tool fastening acknowledged and widely used by the major manufacturers of benders and UPT has obtained the exclusive representation by end users in all Italy. Its solutions intended for press brakes are considered the most innovative in the world in the sector as well as the system patented by Wila, also because it proves to be able to reduce setup times by a ratio corresponding to at least 70% in comparison with standard methodologies, without the need of making use of additional tools to perform the tool change, operation for which it is instead sufficient to press a single pushbutton.

The importance of the made in Italy and international innovation

Established in Piacenza at the end of the Seventies, Tecnostamp ranks among the first Italian manufacturers of tools for benders. In Italy Tecnostamp operates in three different sites: in addition to the head office, it relies on a new milling unit and a grinding centre, both equipped with the most cutting-edge automation techniques. In the world, the Piacenza Tecnostamp is present in 40 Countries and collaborates with partners of absolute relevance to implement complete and integrated solutions supporting the business of customer-companies; besides, it offers a line of special tools designed and implemented upon customers’ demand, tested to assure their correct operation. From Birmingham, England, comes the manufacturer brand Rolla-V, whose dies use a single process that involves two semi-circular devices that support the material during the whole bending process, winding the component around the blade. And all this allows eliminating marking signs even on materials like aluminium and galvanized steel. Wing Bend dies, of which UPT is once more exclusivist in the Peninsula, offer an innovative bending concept that consists in avoiding sheet metal oscillations and in simultaneously winding the component around the blade during the entire bending phases, thus permitting to carry out bends close to holes or grooves without the minimal distortion. All that is possible also in virtue of a design composed by two chrome-plated high strength steel semi-cylinders, which are also supported by two springs in the rotation phase.

A catalogue enriched by new entries

Besides proposing a very broad range of laser spare parts and accessories that range from nozzles to supports and up to lenses, protections, mirrors and filters, up to sensors and cleaning and maintenance kits, UPT supplies also torches, torch bodies and consumables intended for the plasma cutting industry. And with the introduction of Virtek LaserQC into its product family, since last year it has been relying also on a laser scanning system with self-calibration ranking among the most renowned and appreciated all over the world. Not by chance the system is used in sectors like the sheet metal working, packaging, aerospace, tube and seal production; and it has been implemented for the first piece inspection, for quality reports (SPC, ISO and still others), reverse engineering operations and 3D detections (AFM). LaserQC captures more than 500 data per second to allow rapid inspections directly in the production department and performs the scanning of 100% of pieces with a precision of ± 0.05 millimetres. It can therefore represent a reliable solution with low maintenance costs, to be installed directly in the production department, being also able to self-calibrate and to suit any type of environment. The LaserQC AFM system enables three-dimensional measuring permitting to measure heights, distances among the edges or distances among holes inside bent components, in a variety of materials including tubes, sponges for packaging and special cardboards and the AFM technology eliminates the use of manual tools for measuring bent components. Today Virtek LaserQC is used by 800 companies all over the world and is characterized by the easy installation, being ready for use in less than one day. Finally, the user interface is extremely intuitive permitting the user to learn its operation in the lapse of only few hours. Finally, to offer really complete wide-ranging solutions, UPT can supply SOFTWARE for the sheet metal working, starting from the programming of sheet metal cutting machines, punching, laser and bending machinery, automatic nesting to optimize and to reduce the material wastes, to 3D CAD and 2D developments to reach finally the management of the whole production.