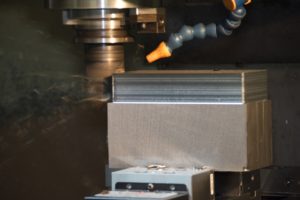

New product SinterGrip by OML is born to satisfy the current need to clamp a workpiece for very few millimeters (with SinterGrip 3,5 mm clamping surface) and this in order to machine the workpiece completely in a single operation (especially for 5 axis machines); in order to save money for the raw materials, especially when they have a big impact on the price (aluminum, titanium, etc.); indirectly to these reasons, and in order to improve the performance of the machine tool and the tools (higher cutting speed + higher feed rate = bigger volume of metal removed = less time to machine the workpiece), the market requires safe clamping, which could at the same time possibly avoid the deformations of the piece itself.

New product SinterGrip by OML is born to satisfy the current need to clamp a workpiece for very few millimeters (with SinterGrip 3,5 mm clamping surface) and this in order to machine the workpiece completely in a single operation (especially for 5 axis machines); in order to save money for the raw materials, especially when they have a big impact on the price (aluminum, titanium, etc.); indirectly to these reasons, and in order to improve the performance of the machine tool and the tools (higher cutting speed + higher feed rate = bigger volume of metal removed = less time to machine the workpiece), the market requires safe clamping, which could at the same time possibly avoid the deformations of the piece itself.

SinterGrip are solid carbide serrated inserts type ISO P30:P35 and coated with method PVD.

The big advantage of SinterGrip is the combination of this material together with its own teeth sharpening, the special tapered shape and the special triangular shape: SinterGrip penetrates into the material of the workpiece and creates some coupling without any clearance, unloading the forces and the vibrations, becoming a sole body with the vise and the workpiece.

SinterGrip can be used on any vice or clamping equipment already existing on the market, only by adding a pair of jaws to be attached to the vice or, using directly the inserts in case of special equipment or chucks.

Therefore, SinterGrip by OML will allow our customers to evolve their existing clamping equipment towards a more safe and stable clamping and to improve the performance of their future clamping equipments. And this by clamping the workpiece for only 3,5 mm.