Dedication, passion, skills and seriousness, handed down from father to son, are the peculiarities that have always distinguished Tecnolame, since it was founded in 1980. Today, it continues to act as a solid base and guide in the evolution towards the near future in the production of industrial blades and tools for sheet metal working.

Tecnolame turns 40 this year and thanks to a mature and consolidated experience, confirms its role as a partner of the most important manufacturers of sheet metal working machines both in Italy and abroad, such as manufacturers of press brakes and shears, stamping presses, but also die-casting presses and flag benders. Since 2008, the company has been operating in its new headquarters in Paderno Dugnano, just outside Milan, in an indoor plant of 2,500 square meters and 4,000 square meters of outdoor space, thanks to a group of 19 employees working in different departments (from milling to grinding, from heat treatment to quality control) to produce special tools for bending, shearing blades and sliding guides.

Tecnolame turns 40 this year and thanks to a mature and consolidated experience, confirms its role as a partner of the most important manufacturers of sheet metal working machines both in Italy and abroad, such as manufacturers of press brakes and shears, stamping presses, but also die-casting presses and flag benders. Since 2008, the company has been operating in its new headquarters in Paderno Dugnano, just outside Milan, in an indoor plant of 2,500 square meters and 4,000 square meters of outdoor space, thanks to a group of 19 employees working in different departments (from milling to grinding, from heat treatment to quality control) to produce special tools for bending, shearing blades and sliding guides.

Owner Vincenzo Di Rosa proudly affirms “In Tecnolame we have always set ourselves the goal of customer satisfaction. This is certainly an important aspect for all companies, but it is even more important when a small company like ours becomes a partner to the most important manufacturers of sheet metal working machines in the world“.

Shear blades in step with the evolution of materials

In this context, the world of sheet metal is constantly evolving. An evolution that takes concrete form, for example, through the increasingly widespread use of new high-resistance materials, rather than being able to satisfy the production of increasingly precise and complex parts. All this without ever forgetting the increasingly tight and compressed timescales.

Di Rosa observes, “these are just some of the challenges our customers face, but they know they can rely on a supplier who will do its utmost to satisfy every last customer. This can also make a difference to the sale of a machine tool. We have achieved a very high level of quality in our shear blades which places us among the major European manufacturers. Our customers choose our product not only for the standard equipment of the new shears, but also for those machines that will have to cut high-strength sheet metal“.

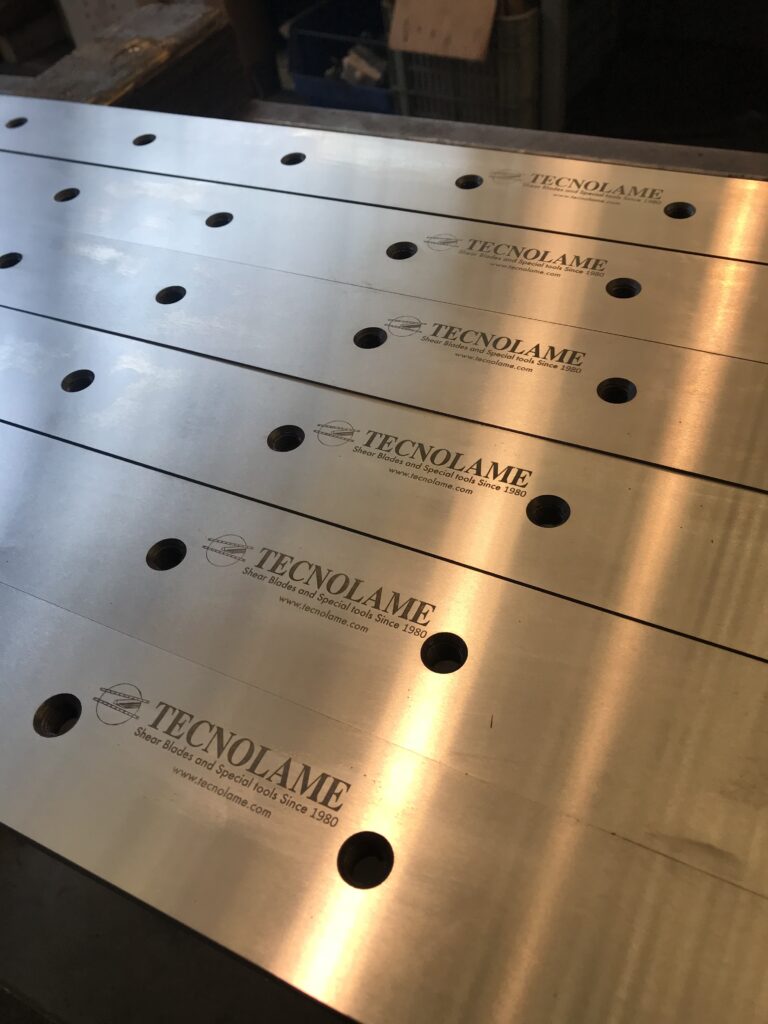

An apparently simple product which contains 40 years of experience in metallurgy, heat treatments, and precise choice of finishes. A product fruit of dedication, passion, expertise and seriousness, handed down from father to son, made with the care and attention typical of the artisan world, seen in an industrial and technological key. All aimed at maximizing the performance of the cutting wire’s life and its precision.

“To achieve these results,” – continues Di Rosa, – “since the beginning of activity it has been decided to carry out and manage heat treatment internally, a process phase that over the years has been increasingly refined with more and more advanced and specific control technologies“.

Another equally important peculiarity is that the shear blades are made with a steel produced to precise specifications, i.e. exclusively for Tecnolame from leading European steel mills.

Uncompromising quality in the service of press-bending

“For press-bending,” – notes Di Rosa himself – “we give a wide range of choice between special tools, for profile or for their high strength, from equipment such as fold-bending tables or specifications for complex profiles. Folding-crushing tables that represent an increasingly used option because it provides a considerable advantage in terms of time, in fact it avoids a specific equipment for crushing“.

Tecnolame also supplies die or punch hydraulic clamping systems and a type of die with automatic variable quarry for high tonnages.

“Precisely in the field of high concentrated carbons,” – Di Rosa intervenes – “we are specialized in providing tools with resistance up to 700 ton/m or tools for the production of large tubes. Itis important in this case to have a generously-sized machine tool fleet that allows us to have few limits“.

In this regard, the company has expanded its fleet in an important way over the years. A continuous integration that today allows to offer to the increasing customer portfolio the possibility to produce also large tools or tools with very long guides.

“With the technologies acquired,” – confirms Di Rosa – “we are in fact able to mill elements up to 12 meters in length and grind up to 7 meters in length. We have also implemented our technical department with the latest generation software and a 3D printer to prototype special equipment, which we often have to realize starting from the last customer’s finished profile. This helps us develop the tools, starting from the profile that the end customer has to make or to make improvements before the product is put into production”.

Innovation by vocation and evolution

As it is strongly devoted to the production of special tools, for Tecnolame technological innovation represents a decisive added value because it becomes an important help to design and manufacture a new product that changes for each client order in a shorter time.

“In this period – concludes Di Rosa – ”we are focusing on the development of two product categories forever dedicated to press-bending machine manufacturers: an automatic variable die of small dimensions that has a low cost and can vary the opening of the quarry in a few seconds, and clamps for lower and upper tools”. Both products will meet Industry 4.0 standards and are designed to be consistently installed on electric press brakes, which we believe will represent a growing market share for this type of process“.

Tecnolame with its great dedication, passion, and seriousness handed down from generation to generation, peculiarities have always distinguished it on the market since it was founded. These elements, alongside its vocation for innovation, continue to act as a solid basis and a guide for the evolution towards the near future.