Arrays of tiny conical tips that eject ionized materials could fabricate nanoscale devices cheaply. Researchers at MIT’s Microsystems Technology Laboratories (MTL) develops dense arrays of microscopic cones that harness electrostatic forces to eject streams of ions. The technology has a range of promising applications: depositing or etching features onto nanoscale mechanical devices; spinning out nanofibers for use in water filters, body armor, and “smart” textiles; or propulsion systems for fist-sized “nanosatellites.”

Arrays of tiny conical tips that eject ionized materials could fabricate nanoscale devices cheaply. Researchers at MIT’s Microsystems Technology Laboratories (MTL) develops dense arrays of microscopic cones that harness electrostatic forces to eject streams of ions. The technology has a range of promising applications: depositing or etching features onto nanoscale mechanical devices; spinning out nanofibers for use in water filters, body armor, and “smart” textiles; or propulsion systems for fist-sized “nanosatellites.”

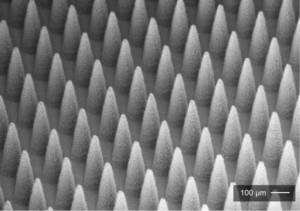

In the latest issue of the IEEE Journal of Microelectromechanical Systems the team described a new prototype array that generates 10 times the ion current per emitter that previous arrays did. Ion current is a measure of the charge carried by moving ions, which translates directly to the rate at which particles can be ejected. Higher currents thus promise more-efficient manufacturing and more-nimble satellites. The same prototype also crams 1,900 emitters onto a chip that’s only a centimeter square, quadrupling the array size and emitter density of even the best of its predecessors.

“This is a field that benefits from miniaturizing the components, because scaling down emitters implies less power consumption, less bias voltage to operate them, and higher throughput,” says Velásquez-García, a principal research scientist at MTL. “The topic we have been tackling is how we can make these devices operate as close as we can to the theoretical limit and how we can greatly increase the throughput by virtue of multiplexing, with massively parallel devices that operate uniformly.”

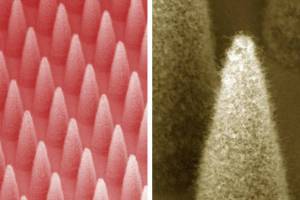

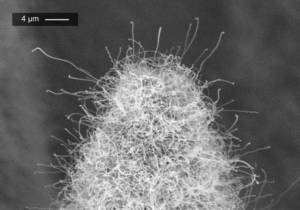

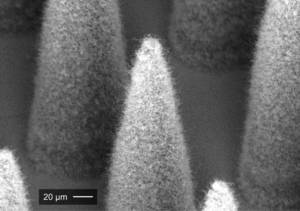

The ions ejected by the research group’s prototype are produced from an ionic salt that’s liquid at room temperature. Surface tension wicks the fluid up the side of the emitters to the tip of the cone, whose narrowness concentrates the electrostatic field. At the tip, the liquid is ionized and, ideally, ejected one molecule at a time. When the ion current in an emitter gets high enough, droplet formation is inevitable. But earlier emitter arrays — those built both by scientists’ group and by others — fell well short of that threshold. Increasing an array’s ion current is a matter of regulating the flow of the ionic salt up the emitters’ sides. To do that, the MIT researchers had previously used black silicon, a form of silicon grown as closely packed bristles. But in the new work, they instead used carbon nanotubes — atom-thick sheets of carbon rolled into cylinders — grown on the slopes of the emitters like trees on a mountainside. By carefully tailoring the density and height of the nanotubes, the researchers were able to achieve a fluid flow that enabled an operating ion current at very near the theoretical limit.

To control the nanotubes’ growth, the researchers first cover the emitter array with an ultrathin catalyst film, which is broken into particles by chemical reactions with both the substrate and the environment. Then they expose the array to a plasma rich in carbon. The nanotubes grow up under the catalyst particles, which sit atop them, until the catalyst degrades.

To control the nanotubes’ growth, the researchers first cover the emitter array with an ultrathin catalyst film, which is broken into particles by chemical reactions with both the substrate and the environment. Then they expose the array to a plasma rich in carbon. The nanotubes grow up under the catalyst particles, which sit atop them, until the catalyst degrades.

Increasing the emitter density — the other improvement reported in the new paper — was a matter of optimizing existing manufacturing “recipe,” Velásquez-García says. The emitters, like most nanoscale silicon devices, were produced through photolithography, a process in which patterns are optically transferred to layers of materials deposited on silicon wafers; a plasma then etches the material away according to the pattern. “The recipe is the gases, power, pressure level, time, and the sequence of the etching,” Velásquez-García says. “We started doing electrospray arrays 15 years ago, and making different generations of devices gave us the know-how to make them better.”

Velásquez-García believes that using arrays of emitters to produce nanodevices could have several advantages over photolithography — the technique that produces the arrays themselves. Because they can operate at room temperature and don’t require a vacuum chamber, the arrays could deposit materials that can’t withstand the extreme conditions of many micro- and nanomanufacturing processes. And they could eliminate the time-consuming process of depositing new layers of material, exposing them to optical patterns, etching them, and then starting all over again.

“In my opinion, the best nanosystems are going to be done by 3-D printing because it would bypass the problems of standard microfabrication,” Velásquez-García says. “It uses prohibitively expensive equipment, which requires a high level of training to operate, and everything is defined in planes. In many applications you want the three-dimensionality: 3-D printing is going to make a big difference in the kinds of systems we can put together and the optimization that we can do.”