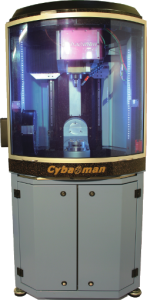

England-based company Cybaman has announced that they will be unveiling a new 6-axis Laser Metal Deposition System at EuroMold, to be held in Frankfurt, Germany, on November 25-28. Metal 3D printing is continuing to make rapid advancements within the industry thanks in part to the competition which has emerged over the last year or so between both startups and long time players.cyba1

England-based company Cybaman has announced that they will be unveiling a new 6-axis Laser Metal Deposition System at EuroMold, to be held in Frankfurt, Germany, on November 25-28. Metal 3D printing is continuing to make rapid advancements within the industry thanks in part to the competition which has emerged over the last year or so between both startups and long time players.cyba1

The company holds international patents for their 6-axis robotic manipulation system, which is used currently within their CNC positioning system called the Cybaman Replicator. Cybaman is taking this technology to the next level. They are implementing it within a new system they call the Cybaman Digital Manufacturing Platform, which can be both additive and subtractive.

This new machine does not utilize metal powders like other popular metal printers on the market. Instead they use an entirely new technique, relying on metal wires to achieve volume deposition as a laser melts each layer of metal into place. They already have made several different types of metal and metal alloys available including aluminum, titanium, cobalt chrome, precious metals, aerospace alloys, PMMA, and zirconium oxcide, with many more materials on the horizon, according to the company.

As for the efficiency of this new platform, Cybaman claims that between 10 and 150 cubic cm of printing can be performed each hour, while the machine also has the capabilities to utilize subtractive methods to complete a manufacturing process. Additional benefits of this new Cybaman Digital Manufacturing Platform include its small footprint, low power consumption, large build envelope (170mm x 170mm x 170mm), quiet operation, remote monitor/control, and its accuracy/resolution. The machine will be compatible with all major data exchange formats including dxf, dwg, iges, sat, vda, STEP, and STL.

This new platform could end up being an all-in-one manufacturing machine, capable of increasing efficiencies within numerous markets worldwide. The ability to streamline both additive and subtractive technologies within one system could cut both fixed and variable costs for a manufacturer. Further details and pricing will be announced at the end of this month in Frankfurt.

Dear sir/madam,

Our company is interesting in instalation of Laser Metal Deposition system and integration of this system in our forging facilities. We would like to have more detailed technical information on capabilities of the system especially in mold repair and coating (to increase tool life) fields. We would also like to have a demo if you have any installed system in Turkey or neighbor countries.

Looking forward for your soon reply.

Best Regards,

Ali Mamedov, PhD