Thanks to the development of a new manufacturing technology, based on cold moulding, Cagnoni will be able to implement commutators by using a minor quantity of copper, with better final characteristics, reduced industrial costs compared to the ones applied on the market today and with both economic and environmental benefits.

Thanks to the development of a new manufacturing technology, based on cold moulding, Cagnoni will be able to implement commutators by using a minor quantity of copper, with better final characteristics, reduced industrial costs compared to the ones applied on the market today and with both economic and environmental benefits.

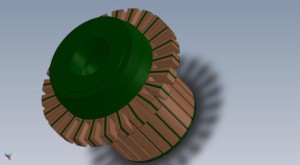

Reference partner in the production of hook-type electric commutators for A.C. and D.C. motors, Cagnoni operates on the market with a very broad range of products exploiting a unique up-to-date technology, which provides for obtaining the internal grips of the commutator bars from that part of semi-finished product that would be then removed by the successive milling phase. In that way, no copper is added to create the gripping itself. That process, developed by Osimo (AN) company itself, will enable a minor waste of raw materials, without affecting the product quality and granting total reliability and extreme flexibility to its customers.

Concerning the sector of electric head commutators, the last decade has been characterized by more and more articulated and interacting competitive factors, summarized in the following points: reduction of sale prices, decrease of component costs, rise of the contents and of the performances of electric motors, increase of the reliability and duration demands. The offer excess compared to the demand, together with the appearance of unbranded products on the market and, especially, of big low cost producers, have determined a price fall and a standardization “towards the middle” of the functional characteristics of products. In this context, the sector companies’ challenge consists in enhancing the quality and the variety of the offered services by seizing, for instance, the potentialities made available by new technologies.

At the state-of-the-art, in fact, the primary manufacturers of electric head commutators use a consolidated technology that provides for the assembly of copper bars (manufactured through cold drawing, successive parting-off and eventual removal of material in excess) around opportune positioning cages; then they proceed to the moulding of the thermosetting resin to fix the position of bars, to the milling to create voids on the head, the undercutting to eliminate insulating material present between one bar and the other, to turning to achieve the final geometry and, finally, to finishing operations.

A technology that certainly allows implementing components that feature good performances and quality but nevertheless, still today, affected by a series of problems and criticalities among which the main ones concern: the use of a big quantity of raw material (copper) connected with the fact that the piece geometry is obtained by stock removal; the need of removing the insulating material from the sliding surface of the brush (undercutting) which implies quite long machining times, due to the fact that the particular product geometry (accentuated head overhang), it is necessary to use cutters with very small diameter (about Ø 10 mm) that perform a very low feed speed (scarce product productivity). Moreover, the undercutting needs a very precise cut positioning, with the result of calling for level electronics (tracking mode cutting) and of producing anyway a certain quantity of non-compliant products. Last but not least, the inner gripping of the commutator bar, realized through a big T-shaped protuberance, it too of copper, which notably increases the mass to be held while rotating.