Dynamic industrial reality living continuous evolution and technological innovation, in 2014 Specialinsert celebrates 40 years of activity inaugurating a modern factory in Turin, in monfalcone 144 street.

Specialinsert was established in 1974 upon the initiative of three sales technicians who, thanks to their experience in the sector of fastening systems, decide to start up their own retail activity of fasteners, over the years transforming it into production and marketing. The adventure started in Turin, with the first headquarters taking up 45 square metres, up to reaching today over 5,100 covered square metres including offices, warehouses and production factory, in three sites located in North Italy, in Turin, Milan and Maerne (Venice).

Technological cutting-edge solutions

Committed for 40 years in the implementation of suitable inserts for the fastening requirements of different materials, the company has maintained the initial specialization in mechanical fastening systems, completing the product implementation on its own with the exclusive product distribution. Equipped with its own production factory, and a study and design office, it destines the majority of its investments in Research and Development, targeted to devise new fastening systems, suitable for the most different application sectors, including also the furniture world. Thanks to a forefront technological laboratory, the manufactured products are constantly tested by the most modern control systems. Relying on its constant commitment in Research and Development, Specialinsert pursues the company mission of standing out on the market as company living a continuous technological evolution and innovation, with the target of supplying its customers with more and more solutions and services keeping pace with times, often anticipating them thanks to technologically advanced solutions.

Made in Italy production

Specialinsert sells in Italy and worldwide and the whole production is completely manufactured in Italy. The business quality system has been certified since 1997 by the certifying body ICIM. Specialinsert can boast a range of proposals that go from threaded tubular inserts to bushings for plastic materials, to coated threads to self-threading bushings, inserts for wood, shear rivets and ¼ quick-turn fasteners. Besides, it can supply products upon customers’ designs and, thanks to the experience of its sale technicians, it can find new fastening solutions wherever requested. The application sectors are really manifold: aerospace, steel structural works, car components, household appliances, electromechanics, electronics, plant engineering, machine tools, transport means, furnishing, metal furniture, building, shipbuilding and several others. Finally, last but not least, another fundamental detail that characterizes Specialinsert, and represents one of the factors at the base of its success, is the presence in its team of sales technicians, directly engaged by the company, who provide targeted advice to identify the most suitable fastening: before the sale to identify the right solution for the customer’s fastening problem, during the product assembly and afterwards to solve whatever eventual problem concerning fastening.

Product novelties

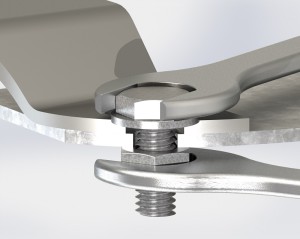

Among the main product novelties, stands out the deformable threaded insert Self-locking Deform-Nut. Devised, patented and produced by Specialinsert, it couples the advantages of the standard deformable rivet with the function of self-locking nuts. Its use provides the possibility of obtaining notable technical advantages: installation on parts without possible access from the inside; (no plastic touch 1) fastening assured by the mechanical fixing on its seat (Test 2 self-locking); rapid assembly of the connection screw because, unlike the self-locking nut, it does not need the aid of two wrenches (double wrench). The wide range of Specialinsert products dedicated to the sheet metal world is further enlarged by the introduction in the catalogue of new product series, including stainless steel version rivet studs of the TCPX series, which represents an excellent technical solution when you need to obtain a male thread on metal sheets and box structures. The assembly, easy and fast, can be carried out with the same pneumatic equipment used for the installation of the insert with internal thread deformation with the aid of specific equipment. Finally, among the novelties it is worth highlighting also the tubular threaded rivets for low resistance materials of the TC/INT series, the particular geometry of the body grants their application also on soft materials (like plastic, fibreglass etc.) as well as on metal sheets and metal box structures.

Tab. – Technical characteristics of the self-locking deform-nut

|

Average tightening torques for a correct installation |

||

|

M 6 |

M 8 |

|

|

Torque Nm |

9 |

18 |

|

Max reference values for steel products |

||

|

M 6 |

M 8 |

|

|

Tensile loads N |

13000 |

21000 |

Braking torques in line with what provided for by the reference DIN regulation

[su_slider source=”media: 1487,1488,1489″ title=”no”]