At Blechexpo 2015, BLM GROUP focused on internationalisation and innovation. BLM GROUP ha summed up its strategy by the slogan All-In-One of integration between the various technologies which contribute to making a part using tubular elements. For BLM GROUP cutting, bending and end-forming is a single integrated process in which the concerned systems interface with the goal of obtaining a finished part which is correct from the first attempt and no longer as a sequence of single, independent jobs the result of which is often obtained by trial and error.

At Blechexpo 2015, BLM GROUP focused on internationalisation and innovation. BLM GROUP ha summed up its strategy by the slogan All-In-One of integration between the various technologies which contribute to making a part using tubular elements. For BLM GROUP cutting, bending and end-forming is a single integrated process in which the concerned systems interface with the goal of obtaining a finished part which is correct from the first attempt and no longer as a sequence of single, independent jobs the result of which is often obtained by trial and error.

The BLMelements software suite is a crucial component in a unique environment which includes the applications used for programming, simulating, managing and controlling system production. The objective is simplifying the operations which lead to making a finished part as a whole instead of a sequence of operations to be programmed separately. ArTube3 is the most recent version of the CAD/CAM package for programming laser tube systems and the heart of the software suite. It can import 3D models of curved tubes and complex tubular structures by breaking them down into the single steps to be performed using different technologies. It extracts the necessary information for making each part correctly from the first attempt and sends it to the various applications. A single integrated environment which shifts the focus from single jobs to the complete part.

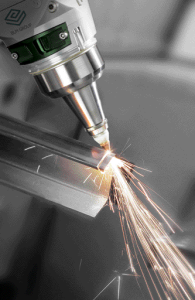

The LC5 sheet and tube laser cutting system displayed at Blechexpo 2015 is the most recent addition to the family of combined systems, an area in which ADIGE-SYS is leader. The LC5, like the sheet-only version LS5, secures performance and functions of absolute quality for cutting sheets. Both are available with 3000×1500 mm or 4000×2000 mm pallets allowing surprising configuration options, layouts and automation opportunities.

The LC5 is a leading system for tube cutting, too. Starting from a bundle loading system, tubes of up to 120 mm in diameter are singled out, loaded, processed and unloaded. Performance is comparable to that of all other Lasertube systems of equal size. With the LC5, the flexibility offered by a combined system is no longer a limit to results.

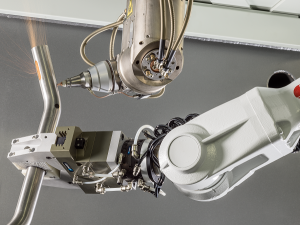

The LT-FREE is the new BLM GROUP system for 3D cutting. The most complete version will be on show at Blechexpo with two robots supporting the double feeding pallet allowing to continuously process boxed parts, drawn sheets, hydroformed sheets and pre-bent tubular parts.

The applications of the system are extremely diverse and the customisation possibilities are considerable.

The LT8 system on shown at Blechexpo 2015 is the pinnacle of the Lasertube family in terms of performance and flexibility. The family features a number of systems for processing tubes of various dimensions with different system automation capacities and cutting technologies which makes the range peerless in the tube laser cutting world.

The LT8 system on shown at Blechexpo 2015 is the pinnacle of the Lasertube family in terms of performance and flexibility. The family features a number of systems for processing tubes of various dimensions with different system automation capacities and cutting technologies which makes the range peerless in the tube laser cutting world.

The performance and functions of these systems, designed to satisfy needs of customers by cutting tubes of diameter from 12 mm to 610 mm, are the result of over 25 years of experience of ADIGE in laser tube cutting systems. ActiveScan, for determining the geometric features of the tube, and ActiveSpeed for simplifying and increasing technological cutting parameter reliability are the most recent innovative functions which characterise some Lasertube family products and consolidate ADIGE’s leadership in the sector.

Despite the absence of bending and end-forming systems at Blechexpo, BLM is still the world leader in tube and metal wire bending and end-forming. The BLM automatic, all-electric bending systems can be used to make curved parts with the target accuracy and quality from the first attempt easily by using the VGP3D programming and simulation system and the B-TOOLS and B-RIGHT packages for correcting errors caused material elasticity and elongation.

In 2014, 82% of the BLM GROUP’s revenue (195 million Euro) was international. Germany is a market of prime importance for BLM GROUP. The BLM GROUP Deutschland GmbH subsidiary based in Unna has a sound sales organisation and a dedicated technical customer care office. Innovation is driven by research and development and approximately 7.5% of the revenue of 2014 was invested in this area. The gaugeable result of this constant commitment is that 70% of the revenue is made up by products which were developed over the past five years only.