Researchers at Fraunhofer Institute have discovered to develop fast, durable mirrors that are capable of performing challenging cutting and welding tasks. Silicon micromirrors can guide laser beams at extremely high speeds, allowing operators to dose heat input to workpieces with absolute precision. But to date they have not been robust enough to be used for laser cutting and welding.

Researchers at Fraunhofer Institute have discovered to develop fast, durable mirrors that are capable of performing challenging cutting and welding tasks. Silicon micromirrors can guide laser beams at extremely high speeds, allowing operators to dose heat input to workpieces with absolute precision. But to date they have not been robust enough to be used for laser cutting and welding.

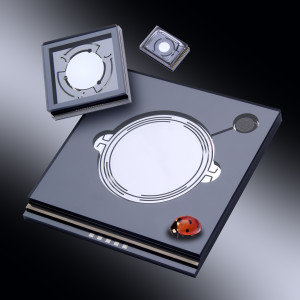

Micromirrors etched from silicon are at the heart of the flexible laser system. Experts refer to them as microelectromechanical systems (MEMS). These MEMS mirrors are scanning mirrors whose job is to deflect the laser beam and guide it precisely over the workpiece. Up to now, it has been possible to use these small mirrors only with laser outputs of a few milliwatts. This was enough for head-up displays on car windshields, but not for laser cutting and welding. Higher outputs would have melted the mirrors. Thanks to a new protective coating developed in the cooperative project and a special mounting, the mirrors are now able to withstand even laser powers in the kilowatt range – enough to process aluminum or sheet steel.

Greater flexibility with micromirrors

A major advantage of the thin MEMS mirrors is that they can be swiveled back and forth at extremely high speeds, reaching frequencies of up to 100,000 hertz. This allows the laser energy to be distributed much more effectively than with conventional laser systems, whose mirrors swivel at only around 1,000 hertz. Lasers have a specific energy profile in their focal point and always input the same amount of energy. If the mirror swivels slowly, the energy cannot be distributed and dosed as effectively at the weld. “By contrast, rapid oscillation of the laser beam allows us to distribute the heat and adjust it to the respective processing task much more effectively,” says Dr.-Ing. Andreas Wetzig, specialist in the laser ablation and cutting department at Fraunhofer IWS.

As demonstrated by laboratory experiments, the MEMS mirrors open up all kinds of possibilities, including for cutting, welding, and surface hardening. “We can weld together aluminum and copper, for example, and use the heat input to precisely control which metal heats up more and thus makes up more of the melt,” says Wetzig. The mirrors also make it easier to weld aluminum alloys alone.

The ability of the new MEMS micromirrors to work with big laser outputs is due not only to their special reflective coating, but also to their unusual size. Normally, MEMS mirrors have a diameter of 1 to 2 millimeters. The new MEMS mirrors have diameters of up to 2 centimeters, enabling them to handle even lasers with larger beam diameters and significantly higher output. For the developers, the challenge consisted in achieving high frequencies despite the size.