Since 3D Printing was first commercialised (in the 80’s) it has grown reasonably slowly, being adopted mostly for small scale prototyping. In 2009, Stratasys’ key patent expired, the market place became flooded with cheap thermoplastic extruders, interest exploded, and the market for thermoplastic filament rocketed. It is expected to reach over $1B by 2025, despite the falling price per kg.

Since 3D Printing was first commercialised (in the 80’s) it has grown reasonably slowly, being adopted mostly for small scale prototyping. In 2009, Stratasys’ key patent expired, the market place became flooded with cheap thermoplastic extruders, interest exploded, and the market for thermoplastic filament rocketed. It is expected to reach over $1B by 2025, despite the falling price per kg.

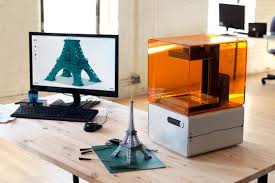

This new interest inspired developments in many technologies to 3D print a wider variety of materials. But not all materials are equal. This report outlines the advantages and disadvantages of printing in different materials, the applications of each, and technical data on the properties of 3D printed materials, which often differ from their traditionally manufactured analogue. These new materials mean there has been space for many new companies, and also many acquisitions by 3D printer manufacturers. Information on start-ups, closures, mergers and acquisitions is included.

No longer is 3D Printing used only for one-off pieces and prototypes, but for final part production of items with reduced and simplified assembly, quicker design iterations, greater design freedom, mass customisation and minimal material wastage. For these reasons, 3D Printing is already common in aerospace, orthopaedic, jewelry and dental sectors. Adoption is fast-growing in education, military, architecture, medical research, and automotive sectors. Nineteen end markets, including all of these have been investigated. The most common applications, technologies and materials vary by geography so the current markets and growth rates are split by region. Changes in use will lead to different growth rates for different materials.

This massive growth in the use and applications of 3D Printers is encouraging a massive growth in the market for 3D Printing Materials. Detailed forecasts, using information from interviews with 50 key players in the industry and disclosed financial information, estimate seven key materials are expected to have a total market of over $8B by 2025. This report includes detailed state of the market, in terms of market value and volume, for:

- Photopolymers

- Thermoplastic filaments

- Thermoplastic powders

- Metal powders

- Sand and binder

- Welding wire

- Plaster

The value chain for 3D printing materials is complicated because several major industrial printer manufacturers engage in “vendor lock-in” in a way analogous to 2D printers, but cheaper 3D printers allow the purchase of free market materials.