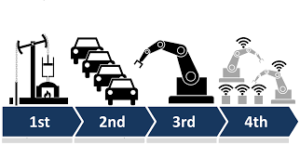

While small and medium-sized enterprises are closer to the beginning of the digital journey, large manufacturers are reaping the benefits of digital technologies. The real and virtual worlds are now beginning to merge in the production world. This is being referred to as the fourth Industrial Revolution, or “Industrie 4.0.” Digital Enterprise is the product portfolio that Siemens offers for this area already today. The idea of digital production has been widely adopted, not only by the automotive industry but also by companies in industries as diverse as machine tooling and printing. One thing these companies have in common is that they are often large and sometimes have offices and production sites in locations all over the world. In contrast, small and medium-sized enterprises (SMEs) have been slow to embrace digitalization technologies.

While small and medium-sized enterprises are closer to the beginning of the digital journey, large manufacturers are reaping the benefits of digital technologies. The real and virtual worlds are now beginning to merge in the production world. This is being referred to as the fourth Industrial Revolution, or “Industrie 4.0.” Digital Enterprise is the product portfolio that Siemens offers for this area already today. The idea of digital production has been widely adopted, not only by the automotive industry but also by companies in industries as diverse as machine tooling and printing. One thing these companies have in common is that they are often large and sometimes have offices and production sites in locations all over the world. In contrast, small and medium-sized enterprises (SMEs) have been slow to embrace digitalization technologies.

More investment needed

In Germany, four out of five SMEs have invested in digital projects over the past three years, according to a study commissioned by KfW Group. However, these investments are modest in their scope. “SMEs are still a long way from fully exhausting the potential of digitalization,” says Dr. Jörg Zeuner, chief economist of KfW Group. As a result, many firms are at risk of “missing the boat,” he adds. Less than a fifth of German SMEs have become digital leaders through investments in digital products, services, apps, or “Industrie 4.0.”

For the rest of the German SMEs to join these digital leaders, they will need to invest more heavily in “Industrie 4.0” technologies. Research from the European Union shows that the necessary investments can be daunting for SMEs, especially because they are unsure how the changes will impact their value chains.

SMEs: a strong economic force

Yet it is imperative that SMEs invest in digitalization. In the countries of the European Union (EU) plus Norway, SMEs account for around two-thirds of total employment and contribute more than half of value added. In the United States, SMEs provide 55% of all jobs and account for 54% of all sales in the country. Statistics are similar in other parts of the world. If this sector falls behind, the consequences could be dire.

Therefore, initiatives have been launched in many industrialized countries to help SMEs make the digital transition. The general aim of these programs is to encourage companies to make greater investments in digital technologies. A starting point for many SMEs on the digital path is cloud solutions.

The cloud as a starting point

At Siemens, MindSphere – the cloud-based, open IoT operating system – enables these applications. First, data defined by the customer are collected and transferred. MindSphere is a key element of the Digital Enterprise Software Suite, Siemens’ offer to all customers on their way to becoming a Digital Enterprise. Then the data are analyzed, and the information relevant for optimization is made available in the form of recommendations for action. Because MindSphere has been designed as an open IoT operating system, it is possible to obtain data from industrial devices from a wide variety of manufacturers, no matter the brand. Moreover, MindSphere provides customers and developers with the capability to develop applications and digital services, apply them and make them available to other users. In this way, totally new service and business models are possible.

Even if a company is not yet ready to use cloud solutions like those described above, experts recommend ensuring that any new equipment purchased is outfitted with sensors and Internet capability so the equipment can be connected at a later date. SMEs that have embraced digitalization say that doing so has brought them many advantages. In a study published by the European Commission, SMEs report that digitalization technologies have fostered entrepreneurship, enabled innovation, created and sustained employment, and promoted global competitiveness. Siemens’ customers show how digital solutions have allowed them to optimize resource usage or reduce downtimes through predictive maintenance.