German sheet metal fabrication machinery company and industrial lasers TRUMPF is setting up a joint venture with Italy’s biggest laser manufacturer SISMA to develop a robust and productive 3D printer for mass production of metal components. In the new enterprise in the additive manufacturing sector, Italian SISMA S.p.A. will hold a 45% stake, while TRUMPF will hold 55% interest. Both partners are bringing expertise, human resources and capital to the joint venture. TRUMPF SISMA S.r.l. is based in Piovene Rocchette near Vicenza, Italy.

German sheet metal fabrication machinery company and industrial lasers TRUMPF is setting up a joint venture with Italy’s biggest laser manufacturer SISMA to develop a robust and productive 3D printer for mass production of metal components. In the new enterprise in the additive manufacturing sector, Italian SISMA S.p.A. will hold a 45% stake, while TRUMPF will hold 55% interest. Both partners are bringing expertise, human resources and capital to the joint venture. TRUMPF SISMA S.r.l. is based in Piovene Rocchette near Vicenza, Italy.

Today, companies from the most diverse sectors are qualifying components and products suited to additive manufacturing rather than the conventional methods utilized until now. The two joint venture partners, with their high level of expertise in laser and mechanical engineering, want to provide robust and productive machines for mass production. “Many machines on the market today are aimed more at prototype construction – explains Dr. Peter Leibinger, head of TRUMPF Laser Technology – In the future, however, the most important criterion where additive manufacturing lines are concerned will be their suitability for industrial applications”.

Several years ago SISMA did begin work on developing an additive manufacturing machine for the production of small metallic components, so the Italian company is bringing this expertise to the joint venture. With annual sales of 33 million Euro and around 1000 laser devices sold each year, SISMA is the biggest laser manufacturer in Italy. The company has around 130 employees and can look back on over 50 years of experience in precision mechanics and industrial automation. The target markets of the innovative laser and systems supplier are primarily jewelry, fashion, dental and industry.

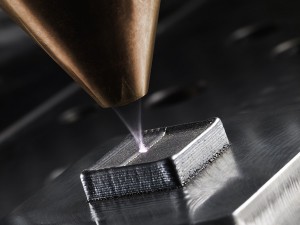

TRUMPF entered the additive manufacturing sector as a pioneer back in the year 2000 with TrumaForm, a universal tool for the generative manufacturing of metallic materials. It was, however, years ahead of its time because the market for serial production of components had not yet developed. At the start of this year TRUMPF entered the additive manufacturing business once again, and is now benefiting from the results of earlier development work as well as from its ever increasing expertise in the related process of laser deposition welding, which is already being used today in all kinds of sectors for repair and coating applications.