A numerical control studied in strict collaboration between customer and supplier grants forefront performances of waterjet sheet metal cutting.

We have recently analysed in-depth the issue of the numerical controls for waterjet sheet metal cutting systems to understand the main innovations in the sector. For this reason we have “become acquainted” with Tecnocut, brand of CMS Industries Group, specialized in the design and production of complete waterjet cutting systems. Mr Stefano Rebuffini, Automazione manager of Tecnocut, explains: «We produce complete waterjet systems equipped with high pressure intensifiers and cutting robots, managed by sophisticated control software. Recently, to further improve the performances of our waterjet cutting systems, we have introduced a new Numerical Control. It is the CNC of the “Series 10” family by OSAI».

A control studied together

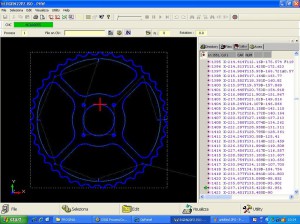

To understand the characteristics and the peculiarities of the new control, as well as the related functional advantages, we had a short interview with Roberto Roagna, Product Marketing Manager of OSAI, who explained us: «The family Series 10 of CNC offers high quality products in a wide range of application sectors. In the specific waterjet case, the CNC by OSAI grants advanced performances from the interpolation point of view, since it allows managing the head motion and the interaction of the rotary axes at best». More precisely, thanks to the active collaboration between Tecnocut and OSAI, it was possible to develop, inside the numerical control, a specific management algorithm of the waterjet sheet metal cutting, in order to improve the productive performances substantially. The optimized head control is certainly one of the main aspects, since it grants more precise and faster sheet metal working. As a matter of fact, it permits an extraordinary increase of the cutting execution speed in case of materials that can be machined with pure waterjet. Roagna confirms: «Higher precision in shorter execution times. It is an excellent result, reached thanks to the partnership that the two enterprises were able to create on that occasion. Now the waterjet machines by Tecnocut have a control, or better, a “mind” purposely studied for them, granting the best mechanical efficiency». But that’s not all. The innovations due to the new CNC are several: today, for instance, thanks to the control by OSAI, it is possible to execute the “preview” of programmes and pieces “on the video”, so that the operator can start and control them more easily. Moreover, in comparison with the past, also the operator interface has been remarkably improved, being clearer, more immediate and rich in functions. «From this point of view – adds Roberto Roagna -, the CNC integrates several interesting functions. Among the most important ones, it is worth reminding the possibility of finishing the machining “in the right point” in case of interruption of the waterjet or for any emergency type. It is a very interesting function, absolutely not “taken for granted”, which allows not wasting material or even entire sheet metals that may be very heavy and expensive».

Highest satisfaction levels

We have already delivered the first systems with the new CNC of the Series 10. Concerning this, Mr Rebuffini specifies: «We have not, obviously, long term results, yet. Nevertheless, the first judgement is more than positive also because, according to the tests carried out by the customer, the results in terms of cutting finish and handling smoothness are very clear and, in the case of the pure water jet cutting, the machining speed has notably improved, even four times higher than in the past. They are excellent results, even better than the expected ones». The validity of the choice is confirmed also by Stefano Dal Lago, who manages the Tecnocut division: «The acquaintance with the control of the Series 10 is the result of several years of collaboration between us and OSAI. The choice of extending the supply also to waterjet machines has been winning, both because the “ base” product was already very good and granted higher level performances and because the product has been further improved and “calibrated” upon the specific waterjet technology. This was made possible by the synergy between the two enterprises, since each of them has deployed its competence and experience, with the result of obtaining a new Numerical Control, with much more options and much more powerful than the one previously used».

OPENcontrol: the new OSAI CNC

OPENcontrol, the new family of OSAI Numerical Controls, is devised to represent a highly scalable platform in terms of SW performances, HW configurations and the broad availability of digital field buses. The OPENcontrol line, natural evolution of the 10 Series, provides better dynamic machine control, integrating further performances for the piece refinishing. Besides, its performances have been notably improved in terms of execution speed, thanks to the integration of new kinematics. Today, the range of OSAI products can satisfy the most different machining requirements in the sheet metal and metal market: not only waterjet machines, but also transfers, high speed machining and processes with Laser and Plasma technologies.