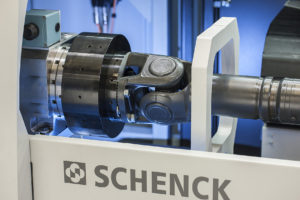

Schenck RoTec presented a new, semi-automatic balancing machine is highly-efficient due to the intelligent combination of manual and automated process steps for the economic quality assurance of cardan shafts. As a fully equipped system solution, Cardano ensures short cycle times in the production, repair and overhaul of cardan shafts.

Schenck RoTec presented a new, semi-automatic balancing machine is highly-efficient due to the intelligent combination of manual and automated process steps for the economic quality assurance of cardan shafts. As a fully equipped system solution, Cardano ensures short cycle times in the production, repair and overhaul of cardan shafts.

Simple operation, with short setup times

The decisive basic factors for reliable and efficient balancing processes with the Cardano are the intuitive operating concept and the easy accessibility of all operating elements. Manual loading and unloading is very simple and convenient to carry out. The very low accommodation depth and diverse assembly deposit points support machine operators in every step of the way. The changeover process of equipment and frequently-changing cardan shaft types is performed swiftly: the length adaptation requires no tools and is quickly performed using easily accessible adjustable hand wheels. The sectional safety door with its large opening allows easy access for the use of peripheral handling and lifting equipment. Through this high level of functionality, the Cardano by Schenck RoTec provides optimal conditions for the realization of faster processes with high process reliability.

The measurement run for the determination of the unbalance on cardan shafts is easy to carry out. The process starts  automatically and ends by displaying clear instructions on correction weight values and proper mounting location positions on the shaft. The basis for this is the Cardano measuring and control unit CAB 950. This intuitive, Operator Interface provides the user convenient and clear access to all machine functions via the touch screen – even during the execution of complex processes.

automatically and ends by displaying clear instructions on correction weight values and proper mounting location positions on the shaft. The basis for this is the Cardano measuring and control unit CAB 950. This intuitive, Operator Interface provides the user convenient and clear access to all machine functions via the touch screen – even during the execution of complex processes.

Another advantage: The correction of unbalances takes place directly on the Cardano. Schenck RoTec equipped the system with a compact medium-frequency welding unit that allows very short welding times with relatively economical use of energy and can be very easily regulated and applied. The machine operator places the previously determined weights into the integrated welding gun and guides it to the stated correction position using pneumatic support. Further process optimizations and cycle time reductions can be achieved through the use of an optional second weld gun and automatic clamp tooling that guarantees a repeatable and precise clamping.

A safe workplace

The new Cardano by Schenck RoTec complies with all aspects of the currently-applicable Machinery Directive; its sectional safety door fulfils the stringent requirements of the DIN ISO 21940-23 (protection against catapulted parts). For damage protection, safety catches automatically enclose the clamped cardan shaft, and a light grid protects the operator when within the danger area. The Cardano’s integrated vibration monitoring system safeguards all machine components that might subjected to high unbalances. Here Schenck RoTec has integrated an additional feature to protect your investment.

For the new Cardano, Schenck RoTec only uses compact, economic drive technology, in combination with modern lightweight construction principles and a consistent reduction of moving masses. This allows us to offer an energy-efficient and highly productive overall solution. Another positive effect of this design is the small footprint of the Cardano, because it is designed as a single piece unit. In this way, the balancing system can also easily be integrated into existing production lines for cardan shaft production.

For the new Cardano, Schenck RoTec only uses compact, economic drive technology, in combination with modern lightweight construction principles and a consistent reduction of moving masses. This allows us to offer an energy-efficient and highly productive overall solution. Another positive effect of this design is the small footprint of the Cardano, because it is designed as a single piece unit. In this way, the balancing system can also easily be integrated into existing production lines for cardan shaft production.