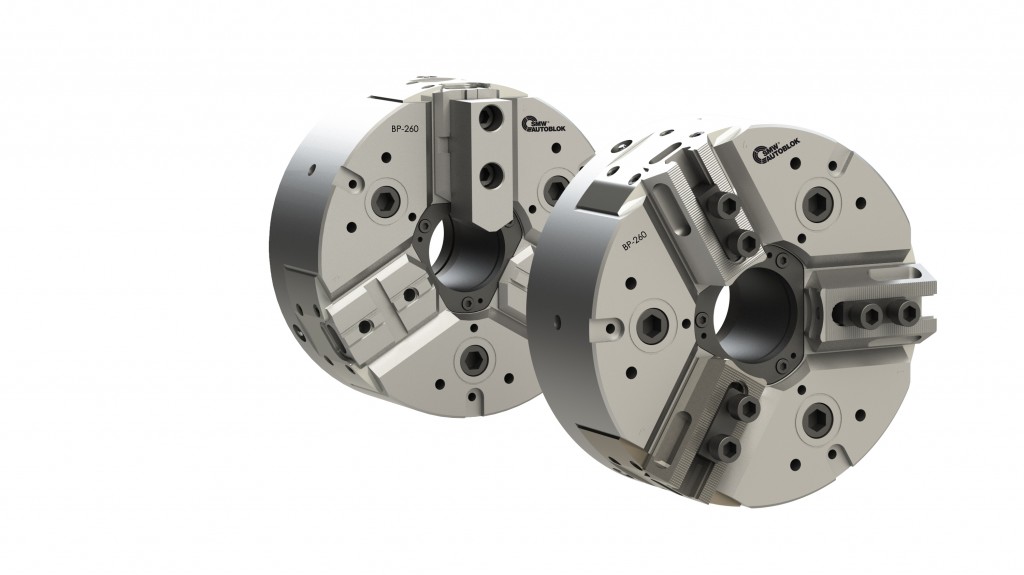

SMW-Autoblok designed and realized the new line of BP chucks.The BP chucks maintain the same basic features as all other “proofline” chucks: constant lubrication and protection from coolant, chips and swarf penetration; constance of gripping force allowing a more constant process accuracy and quality, low maintenance, high productivity thanks to the reduced down-time for maintenance, ecological thanks to the limited use of grease and the absence of grease contamination in the coolant, long service life at high precision, ideal for machining in harsh environment due to fluids, chips and swarf, ideal for machining with high pressure coolant; economical, thanks to the operating life 5-10 longer against a non-sealed chuck. The specific features of the BP chucks are:

• Same through hole as the standard (non-sealed) open center chucks type BH

• Perfect connection to the cylinders type VNK having the same through hole

• Body designed for high rigidity for reduced distortion during clamping and rotation

• Ring wedge with wedge-hook connected to the central part of the master jaws to have the longest master jaw guide in the chuck body to maximize rigidity

• No centrifugal force compensation, but allowing high speed thanks to the light master jaws

• Serrated master jaws version BP-D (inch serration) or BP-M (metric serration) with great flexibility thank to the possibility to clamp small parts (shafts and bars) with collet pads mounted on the central part of the master jaws and to chuck large parts (flanges) with top jaws mounted traditionally

• Tongue and groove version BP-C for even higher speeds thanks to the lighter master jaws

The BP chucks brings all the advantages of the sealed chucks in our “proofline” series also to the open center standard chucks, allowing also standard machines for general use to finally use a modern work-holding system.The BP chucks are available in the following sizes: 170 – 210 – 250 – 315 – 400.