NOVOsphereT, released by Kennametal, empowers shops hungry for real process improvement. Powerful cloud-enabled digital tooling data and intelligence seamlessly interfaces with production, inventory, e-commerce, and more to optimize shop productivity.

NOVOsphereT, released by Kennametal, empowers shops hungry for real process improvement. Powerful cloud-enabled digital tooling data and intelligence seamlessly interfaces with production, inventory, e-commerce, and more to optimize shop productivity.

From better data, better thinking and better decisions. Since its groundbreaking launch in 2013, Kennametal´s NOVOTM digital process planning application has continued growing by supplying complete tool data (milling, turning, holemaking, tools, toolholders, spare parts, speeds and feeds, and much more) digitally, saving process planners, parts estimators, and manufacturing engineers hours of catalog lookups and process guesswork. Now with seamless connectivity via the Machining CloudTM, that same intelligence is driving new efficiencies in part design in CAD/CAM, cutting simulations, presetting, actual machining, inventory management, and e-commerce.

Another major step forward is to feed all these real and potential process improvements back into your shop based on actual data gathered from your own equipment and start seeing where capacities change and efficiencies improve. This intelligence and connectivity has led to NOVOsphereTM, a fundamental step forward in how work gets done.

“It seems that most technology suppliers are rushing to provide some form of digital access to information, but digital access is just the entry ticket,” says John Jacko, vice president and chief marketing officer, Kennametal. “Where Kennametal differs is in its unshakeable focus on how customers can leverage better cutting tool data and information to improve their entire business. NOVOsphereTM is based on an open architecture to deliver just that. NOVOsphereTM is an amazing vision on how far things can go to deliver productivity to our customers.”

Manufacturing process experts have described the current spectrum of digital processing claims as a “feeding frenzy of connectivity and data.” This is driven by a number of things – manufacturing businesses see opportunities for enhanced productivity and reduced time from design to production. More informed businesses add opportunities for providing services and products to better-informed customers – all at much greater speed. Others see value in offering informed analysis capabilities to convert this »firehose» stream of data to a manageable set of results and metrics.

NOVOsphereTM has six essential application to help our customers be more productive:

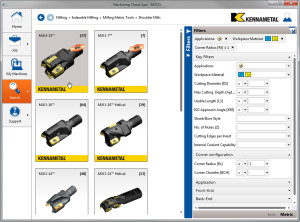

-Select and Advise: This is the stage where users evaluate machining strategies based upon machine, material, part features, and specs. What is the best approach? How long will it take? How much will it cost? Which tools do I need?

-Simulate: This is the stage where users simulate the entire process from end to end with the use of software such as CAM. Are there any dimensional issues? Possible collisions, too many forces?

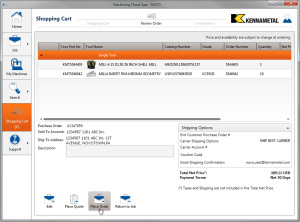

-Inquire and Purchase: This is the stage where users find out what they already have that can do the job and if it´s available in real time to purchase when they need it.

-Optimize: This is the stage where users would like to know how the plan is working. Are we within planned cycle time, costs? Do I use this tool/process consistently across machines/plants?