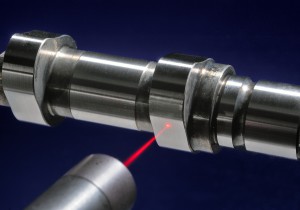

An interferometric distance sensor is developed by the Fraunhofer Institute for Laser Technology ILT. It can precisely measure the geometric features of shafts – for example, camshafts and crankshafts – with sub-micrometer accuracy. The compact bd-1 sensor head can be integrated into shaft measuring machines without any difficulty and also measures surface roughness as well as geometric features. The sensor was demostrated live at the Control 2014 trade fair in Stuttgart.

An interferometric distance sensor is developed by the Fraunhofer Institute for Laser Technology ILT. It can precisely measure the geometric features of shafts – for example, camshafts and crankshafts – with sub-micrometer accuracy. The compact bd-1 sensor head can be integrated into shaft measuring machines without any difficulty and also measures surface roughness as well as geometric features. The sensor was demostrated live at the Control 2014 trade fair in Stuttgart.

The bidirectional optical sensor bd-1, developed by experts of Fraunhofer ILT, can measure both the shape and roughness of shafts inline and needs only a fraction of the installation space that triangulation sensors take up. Its name alludes to the fact that the laser beam moves back and forth along a bidirectional single path. This does away with adjustment problems, as the transmitter and receiver no longer have to be aligned with each other. In direct comparison with conventional triangulation sensors, bd-1 boasts a much lower linearity error value, putting it way ahead of the field.

bd-1 can measure all kinds of surfaces – including finely polished, shining, and reflective surfaces, which can be difficult to measure with other optical sensors. It not only measures surfaces positioned at steep angles and drill holes with high aspect ratios; it also records surface roughness while measuring deviations in shape on rotating shafts – eliminating the need for a separate process step and equipment specifically for this purpose.

bd-1 recognizes deviations in shape and the microscopic surface structure of shafts at speeds of several thousand revolutions per minute with an accuracy in the 100-nm range. This is made possible by high-speed data acquisition and processing and distance measurement frequencies of up to 70 kHz in some cases. bd-1 thus achieves the precision of interferometric sensors and is faster than conventional absolute-measurement distance sensors. bd-1 can be used both for quality inspection on the assembly line and for process monitoring during manufacture. The sensor also works reliably in rough environments. The window for the beam outlet and inlet has a diameter of < 5 mm and can therefore be effectively protected against dirt by means of an air current.

Fraunhofer ILT developers created the distance sensor primarily for manufacturers of shafts or of high-precision cylinder coordinate measuring machines (CCMMs) for components such as camshafts and crankshafts. bd-1 is ideally suited to the 100-percent inline inspection of geometric features in accordance with the requirements of the automotive industry. In field tests, bd-1 has already proved how effectively it can measure the thickness of rolled strips and blown films inline, or carry out roundness and distance measurements during the manufacture of turned parts in machine tools.

Very interested in more information and where to get all details and pricing in the UK for a shaft measuring application which currently uses a DTI mechanical system.

Terry