The manufacturing industry could take advantages of the digital era over the next two decades. This is the aim of the roadmap released by Diginova, a Germany-based consortium of European companies and universities. According to this vision, the market is moving toward manufacturing highly customizable, on-demand goods that are locally produced from raw materials and globally distributed digital designs. This could lead to extreme product customization, decentralization of production and much lower costs of everyday goods in many fields. The industrial revolution introduced a highly effective way of driving prices down. This involves very large capital investments, high energy use, extensive amounts of repetitive manual labor, long distance transportation, and the underlying assumption that the consumer base is sufficiently large and homogeneous.

The manufacturing industry could take advantages of the digital era over the next two decades. This is the aim of the roadmap released by Diginova, a Germany-based consortium of European companies and universities. According to this vision, the market is moving toward manufacturing highly customizable, on-demand goods that are locally produced from raw materials and globally distributed digital designs. This could lead to extreme product customization, decentralization of production and much lower costs of everyday goods in many fields. The industrial revolution introduced a highly effective way of driving prices down. This involves very large capital investments, high energy use, extensive amounts of repetitive manual labor, long distance transportation, and the underlying assumption that the consumer base is sufficiently large and homogeneous.

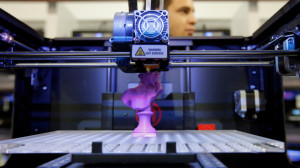

Manufacturing can benefit from the more and more digital world with the introduction of disruptive technologies like3D printing. In the same way that music, photography and printing industry have been revolutionized by the switch to digital technology, so will the manufacturing industry. More precisely, it could be heading toward a global distribution network of digital designs and specification files that will form the basis of local production. Large scale production will become less economically advantageous, making smaller production and customized products increasingly competitive, heading toward low-carbon and zero-waste manufacturing.