Success in the marketing of products and services requires the specific combination of talent, industry expertise and teamwork utilizing innovative processes and technology. All of these components determine the return on investment in R&D as well as the financial strength of the organization. This is the conclusion of the Global Innovation 1000 study by the New York consulting firm Booz & Company. ABB Ltd. (Asean Brown Boveri) provides eloquent testimony to this approach.

Here is an example from the ABB sheet metal manufacturing service operation PAS-MB located in Kleindöttingen in the Swiss canton of Aargau.At the end of 2012 a new 4,000 square meter facility was put into operation with 34 employees dedicated to a total range of sheet metal processing for electrical components and electrical housings e.g. rail vehicles, mill drives used in mining and electric motors in general. In addition, components for turbo chargers and transformers for power generation are manufactured at the new facility. ABB operates not only as an internal supplier, but also as a service provider and contract manufacturer for many international customers. Recently, the ratio of consolidated internal order processing compared to external client orders rose from 25 to 75 percent, after previously outsourced production was brought back in-house. «We are to a certain extent unusual and unique within the ABB organization as a service provider at this level for sheet metal processing» explains Thomas Strittmatter, Manager of Production Logistics, Production and Quality combined. «With the investment in and implementation of the new facility, the division is established as a model manufacturer of precision parts and components as well as a partner for complex manufacturing concepts».

Continuous Process Chain

Throughout the operation, the impressive flexibility of the systems are combined with the immense expertise of the technical staff on Strittmatter’s team. This combination enables innovative solutions as well as creating space for small runs and special projects. The trained metal worker, TS technician (Department of Energy) and business manager, explains the machinery and thus the scope of services:

Engineering

Save time and costs: The production-oriented product development is done in close cooperation with customers and uses both 2D and 3D CAD-based in-house sheet metal processing programs resulting in economic, attractive and innovative solutions.

Flat metal working

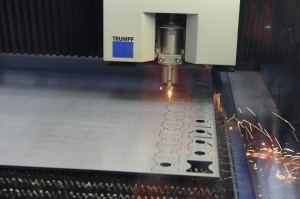

Provide maximum benefits: Technological diversity through the use of laser cutting, CNC punching, laser/punch, laser measuring system, excenter and hydraulic presses as well as automatic presses.

Forming

Customized consulting and Methods: CNC-based manufacturing techniques for bending, rolling, embossing and deep drawing are utilized at ABB in Kleindöttingen to meet the specifications of different modules.

Joining

Guaranteed high customer benefits here: Investments in state-of-the-art technologies for riveting, welding, soldering, spot welding and clinching provide flexible solutions for various challenges.

Finishing

Realizing Customer requests at ABB: Operations such as brushing, color treatments, galvanizing and debarring can be implemented in-house or with accomplished partners.

Key Factor- Quality

ABB’s quality management system covers the areas of environmental protection and occupational safety. The company is certified according to ISO 9001, ISO 4001 and OHSAS 18001 standards, and also maintains the welding certification EN 15085.

[su_slider source=”media: 646,645,647,648,644″]

Specifically in flat metal processing, quality control, material testing and documentation are provided by the highly flexible LaserQC laser-based measurement system manufactured by Virtek Vision International in Canada. «Through the speed, accuracy, documentation capability and achievable repeatability of the LaserQC, which detects up to 540 reference points per second, we secure a significant competitive advantage as a service provider» explains Sebastian Haase at ABB quality assurance. «Where we have previously worked with time-consuming calipers and height gauges, we are now far more responsive and benefit from the precision of the laser system in the range 0.01 mm on average, which optimally reflects our needs», indicates the Quality expert. Although the specified accuracy of the system is +/- 0.05 mm, this is related to an individual measurement point under worst conditions. As the LaserQC system takes many measurements and uses a Gaussian distribution calculation (with other options as well) it manages the difficult measurement of holes and circles with a much higher accuracy than specified. An operator taking normal single point measurements with a metrology instrument is not able to produce as many reliable data points.

Concentric Circles

An example of the LaserQC System performance in fulfilling the most demanding customer requirements is noted here: In an application for the production of rotors, the challenge was to ensure the concentricity of inner and outer circles, and to measure and document the actual results accordingly. What even experienced users may see as comparable to “squaring the circle” was a task solved with the LaserQC to the highest level of precision automatically by calculating average values.

Technology and know-how transfer: Partnership with Trumpf

An additional asset in the game: ABB has a close partnership for technology development and know-how with the company Trumpf, whose laser cutting machine is used. In this way ABB employees are supported in their aim of continuous improvement. As an example, the entire ABB Kleindöttinger team visited the Trumpf factory in Graubünden in 2012. In addition, it manufactures parts for laser machine tools for the world’s leading supplier. Limiting process automation to where it makes sense without constantly reacting to changing market demands and individual requirements is also another strategy for the ABB operation. Thomas Strittmatter states: «Full automation is not our strategic goal; we restrict ourselves deliberately to laser-assisted cutting and punching.» It is clearly recognized that maintaining a competitive advantage compared with low-wage countries requires specialization and cost- effective small batch size implementation.

Conclusion

The business environment of a global player such as ABB requires clear strategies and concepts. The best tools, equipment and state-of-the-art systems are the key to success and sustainability and a requirement for timely fabrication of components and products.