Small data from smart sensors can improve packaging machinery performance. Let’s take a look at how. Continuing developments in sensing technology have fueled user expectations in nearly every industry, and packaging is no exception. Intelligent sensors are allowing packaging machinery manufacturers and their customers to get more data from individual sensors via a variety of interfaces, resulting in operational improvements.

Small data from smart sensors can improve packaging machinery performance. Let’s take a look at how. Continuing developments in sensing technology have fueled user expectations in nearly every industry, and packaging is no exception. Intelligent sensors are allowing packaging machinery manufacturers and their customers to get more data from individual sensors via a variety of interfaces, resulting in operational improvements.

Connectedness is growing in nearly all industries, and packaging original equipment manufacturers (OEMs) are responding by developing smarter, more automated machines and lines of all types. The components that go on the machines need to be smarter as well, starting at the sensor level. Some smart sensors can send information beyond just the sensed parameter, either via a digital data link or hard-wiring. Other smart sensors have internal intelligence that maintains sensor performance by automatically adjusting for varying conditions. Still other smart sensors combine these two attributes to create intelligent sensors with added communication capabilities. All of these types of sensors generate small data, which is aggregated to create Big Data.

Big Data and the Internet of Things (IoT) are terms bandied about with abandon in a host of industries, and in packaging systems, most Big Data originates as small data at the sensor level. Sensor data is communicated to control and monitoring systems and these systems aggregate this information to create Big Data. This Big Data is used by operators, by plant personnel and by other employees throughout the enterprise. This is the industrial IoT at a packaging plant level, and it provides a host of benefits. Smart sensor information is used to reduce downtime, improve machine performance and implement predictive maintenance programs. Smart sensor data is also be used to ensure safety, improve product quality and increase throughput. Realizing these benefits requires an understanding of how smart sensors work, and how to best use the data they generate.

Smart sensors send data, increase productivity

With smart sensors, data is no longer locked inside the sensors, but can instead be sent to control and monitoring systems via either a digital data link or hard-wiring. Common digital data links include CAN, IO-Link, Profibus and various Ethernet protocols. Increases in productivity can be gained with smart functionality such as parameter cloning, remote parameter changes, line changeover and predictive maintenance to name a few.

- Parameter cloning: This allows automatic backup and restoration of sensor configurations via digital communications between the sensor and the control system. When a sensor is replaced, all of the parameters specific for its operation in the particular application can be downloaded from the control system. This reduces downtime during replacement or changeover, and it ensures correct parameters are entered.

- Predictive maintenance: Many smart sensors have a health output, with diagnostic data relating to sensor health sent to the control system. This allows early detection of dirt build-up on the sensor, which helps prevent unexpected downtime due to required sensor maintenance. Implementing this type of predictive maintenance allows adjustments, cleaning or repairs to be made before a failure causes downtime or defective product. It also allows maintenance to be scheduled and performed only when needed. The alternative is to run to failure, or to perform maintenance much more frequently than required. These sensors are smart because they communicate information in addition to the sensed parameter.

- Automated line changeover: Flexible adjustment of smart sensors by the control system allows remote and automatic modification of parameters such as sensing range or threshold setting. This feature applies to distance sensors, contrast sensors and photoelectric sensors.

A common use of this function is with recipes, as sensors can be quickly adjusted based on recipe parameters to optimize production of each type of item. Many packaging machines use recipes to quickly changeover from one product to the next, and in many cases this requires adjustments to sensors. For example, a single packaging line might need to accommodate products of various shape sizes, colors and surface textures. If a recipe change affects any of these attributes, sensor adjustment is often required. Without flexible adjustment, these changes have to be made manually. Not only does this increase changeover time, it also adds to labor requirements and increases the possibility of error. Automatic flexible adjustment of sensors by the controller eliminates these issues.

- Remote teach-in: Remote teach is another use of the flexible adjustment function, as sensors can be taught without disassembling a machine or entering an unsafe area.

With either use, downtime is reduced and throughput is increased because adjustments occur quickly. Labor costs are cut and quality is improved because adjustments are made automatically instead of manually, and safety is enhanced because operators don’t have to be in close proximity to operating machinery to make changes.

Intelligent sensors improve operations

With intelligent sensors, internal smarts are used to automatically maintain sensor performance in varying conditions. For example, continuous threshold adaptation photoelectric sensors automatically adapt to varying conditions to maintain consistent performance. In the event of contamination, the sensor adapts to the new conditions and continues operation, so maintenance is only needed if the sensor becomes heavily contaminated. These sensors also feature automatic adjustment of the original thresholds after cleaning.

A photoelectric sensor with a self-adjusting light spot increases or decreases its light intensity based on the color of the object, providing precise and reliable detection regardless of the object’s color or level of shininess. Features like this can easily be used to increase machine performance. There are many types of smart sensors as discussed above, and many others not covered in this article due to space constraints. The following section gives two detailed examples of how smart sensors are used in specific packaging machine applications.

Smart sensors in action

To ensure correct product insertion into a carton, the product and the carton need to be detected for presence to ensure insertion synchronization. Product variability in design and form—and packaging design variability in color, shininess and texture—present sensing challenges as false detection or multiple detection of a single product can occur. A smart photoelectric sensor from SICK was used by a cartoning machine OEM to address these issues.

A short pulse diffuser LED with a 16-element receiver array monitors potential passive interferences from moving guide chains or pitch guides that move product and cartons. The sensor uses onboard intelligence to determine the positions of interference and eliminate them. The main sender LED detects a possible static background and registers its position, while simultaneously looking for the target object in the defined sensing range. The main sender LED in conjunction with the short pulse diffuser LED automatically adjusts brightness of the lightspot depending on the background, object color and/or shininess—resulting in reliable detection without the need for frequent adjustment.

At the top of the smart sensor class are those intelligent sensors with digital communication capability, providing the highest level of sensor performance.

A vision for smart quality-control applications

While traditional photoelectric sensors with intelligent functionality are becoming more common in manufacturing, smart cameras have already gained more widespread use in the packaging/food and beverage industries. These sophisticated sensors combine digital communications with intelligent functionality. An example is SICK’s line of machine vision products, which are used in a host of packaging applications.

Volume and dimension measurement can be used to detect and reject over-sized products that could cause jams in tray loaders. These measurements can also be used to find broken wafers, crackers or cookies before they are packaged.

In a cracker packaging line, cracker height can be measured to ensure that all crackers will fit into the package. These measurements can also detect small systematic height errors that can add up and cause problems, as too large stacks can cause broken product or packages. Measuring dimensions and shape can find below spec crackers prior to packaging, and measuring inter-cracker distance can find crackers that are too close to one another or piggy-backed.

Measuring dimensions and shape can find below spec crackers prior to packaging, and measuring inter-cracker distance can find crackers that are too close to one another or piggy-backed.

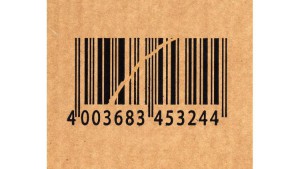

Smart barcode quality application

Nearly every product or package created today has a barcode associated with it for identification, packaging, track and trace, inventory management, automated sorting and more.  Labels can be wrinkled and are sometimes subjected to abrasion and loss of quality during packaging processes. What if you could get better reading performance even when codes are poorly printed, partially hidden or tilted? Some barcode scanners manufactured today offer smart code reconstruction algorithms. This enhanced technology reads damaged and partially obscured codes, increasing read rates. The code quality is indicated through the diagnostic data directly from the scanner. Smart sensors are delivering significant benefits now in real-world applications, but there’s more to come.

Labels can be wrinkled and are sometimes subjected to abrasion and loss of quality during packaging processes. What if you could get better reading performance even when codes are poorly printed, partially hidden or tilted? Some barcode scanners manufactured today offer smart code reconstruction algorithms. This enhanced technology reads damaged and partially obscured codes, increasing read rates. The code quality is indicated through the diagnostic data directly from the scanner. Smart sensors are delivering significant benefits now in real-world applications, but there’s more to come.

The future of smart sensors in packaging

The range of currently available smart sensors can be used to improve virtually all aspects of packaging machine operation. Networking these smart sensors to control and monitoring systems through either digital data links or hardwiring creates an industrial IoT at the plant level. This transforms small data from sensors into big data used to improve not only individual machine performance, but entire packaging line operation while creating transparency throughout the entire machine. As technology progresses, more and more sensors will be equipped with digital communications technology. These sensors will also become more powerful and intelligent, allowing them to gather and process even more data, and to communicate this information to not only the control system, but also to other platforms. These platforms can range from manufacturing enterprise software (MES) and enterprise resource planning (ERP) systems, to hand-held devices like smartphones and tablets.

Sending data to higher level platforms allows for sophisticated data analysis, revealing opportunities for performance enhancements not easily detected by manual observation. Communicating information to handheld devices lets employees monitor and manage packaging machines and lines from anywhere, greatly improving response times and efficiency.