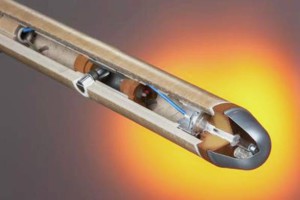

Heraeus presents its new QuiK-Lab system, which consists of a high-end spectrometer with an automated calibration and a sublance sensor. Apart from bath temperature, the sensor can also register liquidus temperature or oxygen content of a preparation-free sample. With this innovative system, the operator of the convertor knows within 1 minute not only the bath temperature and the liquidus temperature, but also the Mn, P and S content of the molten metal.

Heraeus presents its new QuiK-Lab system, which consists of a high-end spectrometer with an automated calibration and a sublance sensor. Apart from bath temperature, the sensor can also register liquidus temperature or oxygen content of a preparation-free sample. With this innovative system, the operator of the convertor knows within 1 minute not only the bath temperature and the liquidus temperature, but also the Mn, P and S content of the molten metal.

The QuiK-Lab comprises a high-end spectrometer, which is automatically calibrated over a period of several months with the help of a robot and specially developed calibration standards. The big time gain in chemical analysis is realized, because the QuiK-Lab is located on the shop floor and the sample does not require any sample preparation such as grinding or milling.

This accelerates and increases the production of steel, because the industry has no longer to wait for the test results from the laboratory. Simultaneously the manufacturing process improves, because important information about the steel composition are immediately available. Honored with an innovation award from Heraeus in 2013, the technology group now makes available this marketable innovation for the steel industry at GIFA.

Heraeus Electro-Nite offers a wide range of different probes and instruments for use in iron foundries. There is even more to discover at the fair, for example the “Qube”. This is a system to link the measuring probe wireless (WLAN) with the measuring instrument. Thus, Heraeus continues to work to consistently improve the network between foundry and laboratory.