Cut-to-length blanking lines and combined cut-to-length lines, blanking lines with straightening and flying shears, recoiling and special lines for the treatment of all types of sheet metals. These are the machining plants for sheet metal coils and for small productions and handcraft that Gabella Macchine can design and develop according to specific needs, proposing itself as technological partner with over half century of experience behind.

The history of Gabella Macchine starts in the distant Thirties, in a valley at the foot of Monte Rosa in the upper part of Piedmont when a young craftsman bends and cuts sheet metal for the covers and the small productions and handcraft that he installs in the local textile factories. The cleverness of this young man, Mario Gabella, makes him guess the contrast between his work and the mechanization of the companies where he operates; therefore the first “mechanisms” were born from his inventiveness. Shortly after the war unfortunately interrupts his projects and compels him to a hard peregrination throughout Europe. This terrible experience however reveals a positive side, permitting him a direct dialogue with other cultures and, especially, puts him in contact with other technologies. Once come back to Italy, he believes that the future of the sheet metal resides in coil and that steelworks will distribute the coils directly to the users; this will require suitable machines for the use in small and medium industries.

From the first press brakes…

«In the meantime – reminds Paolo Gabella, one of the owners and member of the third generation together with Amedeo and Letizia, who today manage the company –Crevacuore factories, grown and reorganized, produce the first press brakes for thin sheets. They are fully innovative machines for that age, especially for the capacity of working sheet metals up to 10 metres». Few years later, at the beginning of the Seventies, Mario Gabella, followed in his entrepreneurial idea by his sons Norberto and Giorgio, accomplishes the true revolution in the sheet metal slitting with the mobile head slitter: unique machine in the world that can be positioned automatically by Numerical Control or, more simply, by a motor. It is a result of an experience boasting a development based on the slitting on millions of metres of any material kind. Some years after the first suffered idea, the slitter has continued its evolution by widening the range of workable thicknesses and improving the potentialities already owned by the prototype. «The research goes on – adds Gabella – together with the manifold practical applications that protect this solution from any attempt of possible imitation. The operation of this slitting system is in fact obtained only with appropriate tolerances, with the use of tested materials and other small secrets that make it absolutely reliable. Starting from the Nineties electronics has then led these products to be even more appreciated by customers worldwide». The new generation, actively operating in the company structure since the early 2000s, has in the meantime given a decisive boost to widen the range of products manufactured by Gabella Macchine. With a continuous bent for suiting the market indications and producing plants fully designed according to customers’ requests, that’s to say always attributing great relevance to innovation and flexibility to satisfy production requirements. In this way the company succeeds in satisfying both the small craft firm as well as the most automated production company and in helping them to find the right solution.

…to a recent successful case

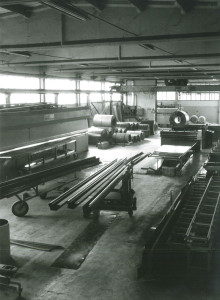

Today Gabella Macchine is a company that employs 45 people working in the sales and administrative office, technical design office and production workshop where they carry out also the testing of the produced machines. Nowadays the production boasts great experience in the creation of combined blanking and cut-to-length lines, blanking lines with straightening and flying shears, recoiling lines also with standard slitters and special lines for the machining and treatment of all types of sheet metals up to four millimetres of thickness. «Among them – further adds Paolo Gabella – a successful case that we like telling and that exemplifies the way of working shares the historical roots, that’s to say they too dating back to three generations ago». The company Revolti, established in 1948 as small craft firm, is a Trento company specialized in the sheet metal and metal working with a long tradition in building plumbing. For three generations the homonymous family has been working in the sector of plumbing and metal working: initially carrying out the activity as posers and today especially as suppliers of sheet metal for tinsmiths and for building projects of various sizes. «In 1948 – explains Gabella – Tarcisio Revolti started his activity in the plumbing and copper working sectors and some years later he obtains the first important job order that will give luster to the firm: the dome of the Cathedral of Brescia». In 1979 the small craft workshop becomes a company, ruled by the founder’s sons. The first 600 square-metre shed is completed by others, in compliance with the needs of constant and continuous growth. Revolti Lattonerie has never stopped investing in innovation and in development and today, with the new generation, it can boast the construction of a new widened production site, built in 2012, allowing it to approach the market with higher competitiveness. Thanks to the passion and the experience of skilled and efficient personnel and with an innovative propensity backed by the cutting-edge technology of machines, it grants a production of semi-finished and finished products standing out for excellent quality and utmost reliability. Just in the business growth Gabella Macchine plays the role of technological partner, since it has been supporting Revolti family in their entrepreneurial idea since the beginning. «Revolti Lattonerie – adds and ends Paolo Gabella – can then offer a “just in time” service, and satisfy all requirements submitted by customers with the best care, from the cost analysis to the final assembly, the main target is to become a real partner for each customer. Just as also our company always tries to do». It is in this way that Revolti has always been able to fulfil its target of granting supplies and services of excellent level. For over sixty years they have been successfully working in the sectors of plumbing and metal working, assuring a high quality service that can be customized to meet the various requirements.

A new plant for a further growth

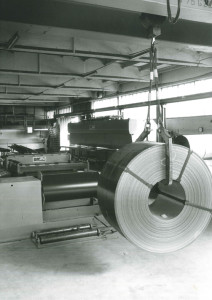

With the precise target of increasing the supply of sheet metals and metal products intended for the building industry in the sector of coverings, coatings and rain systems, just from 2012 to 2013, with the completion of the new productive site, Revolti once more decided to turn to Gabella Macchine. It has in fact chosen the Crevacuore company again to buy an innovative slitting and recoiling plant. The main characteristics of the new slitter are the increase of the working speed and of the capacity of the decoiler and recoiler, the increase of the number of slitting heads and the automation of the management mechanisms of the coils to be recoiled. The needs and the requisites were definite and precise, and the work was a continuous dialogue, with mutual satisfaction of all parties at stake; this in order to let the end users of Revolti Lattonerie benefit from the operational and productive possibilities that the new line designed, developed and manufactured by Gabella can grant. Therefore, in some years the adventure of the new generations will go on, availing themselves of new resources.