New CAM software helps Robin Technologies take on greater challenges

Founded in 1980 by Damien Robin, Robin Technologies is based in the county of Chantonnay in the Pays de Loire region, which is the third largest industrial region in France. The company focused for several decades on manufacturing molds. After the mold market became less profitable due to intense global competition, Robin Technologies began to apply its skill in Wire-EDM and 2 to 5-axis milling to subcontract machining of complex parts. The Pays de Loire region is home to major manufacturing companies such as Airbus, Total and the Saint Nazaire shipyards. Robin Technologies became a contractor to these and other manufacturers, providing precision machining services. Robin Technologies currently uses 15 numerically controlled machine tools, mainly from ONA and MAZAK, to manufacture aeronautical maintenance tools, dies for the agri-food industry, gearbox parts for the automotive industry, and various parts for the robotics and cosmetics industries. The managers at Robin Technologies continuously invest in the latest CNC machines, new manufacturing technologies and employee training. Tony Jourdain, production manager, explained: “My priority is to give our teams everything they need to be as productive as possible, including the latest production technologies and training in equipment and programming. The right CAM solution is a key part of achieving these goals.”

A Smart CAM Investment

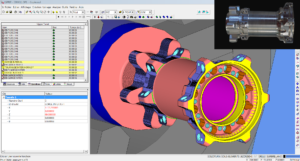

Robin Technologies selected ESPRIT because its complete functionality in milling, turning, multitasking, wire EDM, swiss-style and B-axis machines enables the company to run its entire machine shop using only one CAM software package. After purchasing ESPRIT, Robin Technologies successfully took the leap to 5-axis and 3D machining, a strategic choice that enables the company to meet the demands of the multiple industries that sustain the Pays de Loire region. “ESPRIT helped us improve our multitasking skills on our MAZAK Integrex centers, making it possible to take on more complex projects and expand our manufacturing capabilities,” summarized Frédéric Allard, turning-milling programmer for Robin Technologies. ESPRIT allowed Robin Technologies to minimize configurations, tools, maintenance and time not devoted to cutting on its MAZAK Integrex machine tools, each of which includes two turning spindles for all-in-one machining and a lower turret. Another strength of ESPRIT is its post-processors, which are tested and certified by the machine tool manufacturer and are open source so they can easily be modified by the user. “ESPRIT gives us great flexibility,” says Sébastien Giraud, head of EDM at Robin Technologies. “Currently we have three EDM machines of different brands. The post-processor provided by ESPRIT lets me move programs from one machine to another without difficulty.” ESPRIT also enables Robin Technologies to maximize the capabilities of its ONA Wire-EDM machines. “ESPRIT has allowed us to produce sophisticated parts on our ONA 4-axis Wire-EDM machines to high levels of precision,” Giraud said. Damien Roure, Head of ONA France, added: “ESPRIT and the Usiprog distributor help our machines handle increasingly complex wire cutting. The ESPRIT teams are attentive and react quickly to our problems and those of our customers. The fast response of the ESPRIT teams is, along with the performance of the software itself, the strongest point of our partnership with ESPRIT.”

Meeting New Challenges

Soon after Robin Technologies implemented its new CAM solution, Airbus consulted with the company about producing a very complex gauge which could only be machined using 5-axis milling. With the help of their sophisticated machine tools and ESPRIT CAM, the Robin Technologies team delivered the part on time and met the quality and cost requirements of the customer. Advanced training courses enable Robin Technologies programmers to accept even more difficult challenges. For example, they were recently contracted to program a competitive mountain bike wheel hub that required milling and turning many complex faces with the most complicated operations being the Z-level roughing and composite spiral finishing. The ESPRIT support team helped Robin Technologies programmers to further develop their programming skills and program the part in one day. “With the help of ESPRIT reseller Usiprog we can overcome all obstacles,” said Damien Berthelot, CAM manager at Robin Technologies. By adapting its company strategy to changing market conditions and choosing reliable and experienced partners such as ESPRIT CAM, Robin Technologies provides its customers with quality parts at attractive prices. This winning combination has enabled the company to succeed in the highly competitive contract machining marketplace.