Metal laser melting can be used to manufacture complex and efficient lightweight structures. This is particularly beneficial in sectors such as the aerospace and motorsport industries, where every gram counts. Last year, toolcraft decided to start using the Siemens NX software package, in order to improve its process chain, from design and construction to modifications using machining techniques. As a result, the company is now able to produce even more efficient components. This is thanks to the weight and cost reductions enabled by the modules for FEM calculations and topology optimisation built into the software.

Optimisation of laser-melted components

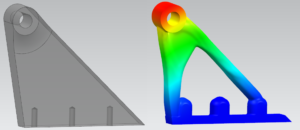

“Special features for topology optimisation and FEM calculations enable us to design optimal components,” explains Ralf Domider, who is responsible for design and simulation in toolcraft‘s metal laser melting division. “These enable us to analyse not only the material being employed and the laser-melted test pieces, but the forces subsequently exerted on the component as well.” The software can be used to reproduce the load paths and internal stresses that later act on the component. The ambient temperature can also be taken into account. Using this data, the program identifies the areas in which the amount of material can be reduced. The simulated results provide detailed information on the stresses and strains exerted within the optimised component. While the level of stress is high in the areas highlighted in red, the green and blue areas depict regions where there is a lower amount of stress. This information enables designers to evaluate the topology optimisation results in terms of functionality and durability, allowing weight to be reduced to the minimum amount possible without there being a detrimental effect on the component properties. In most cases, a safety factor is included in the calculation so that the completed part can withstand an even greater load than stated in the specification.

Lower weight and an optimised design reduce costs

The finite element method (FEM) not only results in lightweight components “losing” weight, but also optimises their design. Designers can use topology optimisation to calculate the most efficient basic shape (topology) of a component, while taking into account the mechanical loads to which it will later be subjected. Besides conserving materials, optimising a component’s design in advance means that fewer modifications will be required once it is produced. For example, there would be less of a need to remove support structures, apply surface treatments or perform any reworking using machining processes. A further advantage of the analysis is the ability to use different materials. The calculations enable designers to ascertain which material would be most suitable for the way in which the component is to be subsequently used. “This not only saves additional time and materials, but further reduces the need for reworking,” says Domider. toolcraft is committed to improving its procedures and the complete process chain, including optical and tactile measuring and non-destructive testing in accordance with NADCAP. Component quality is crucial, especially in applications where safety is of vital importance or certification is required. This is why toolcraft also assesses the dynamic strength of various metals by performing fatigue testing in its own lab.