At this year’s IMTS Okuma introduced new machines and features. In addition to the premiers at the fair, Okuma also presented its wide product portfolio ranging from various hardware solutions to software and smart factory solutions. In total the trade fair was a full success for the machining expert as more than 4,000 people visited the Okuma booth and the number of sales made at the fair exceeded all expectations.

A definite highlight at the Okuma stand was the new LU7000EX. The powerful 2-saddle lathe was designed to manufacture large parts with a max turning diameter of 900 mm weighing max 11,000 kg. Offering a wide range of spindle variations for cutting demanding materials, the machine is especially suitable for the oil and gas industry. Another novelty shown at the fair was the MB-5000HII, a redesigned horizontal machining centre using very little shop floor space while offering high productivity.

A definite highlight at the Okuma stand was the new LU7000EX. The powerful 2-saddle lathe was designed to manufacture large parts with a max turning diameter of 900 mm weighing max 11,000 kg. Offering a wide range of spindle variations for cutting demanding materials, the machine is especially suitable for the oil and gas industry. Another novelty shown at the fair was the MB-5000HII, a redesigned horizontal machining centre using very little shop floor space while offering high productivity.

Large portfolio

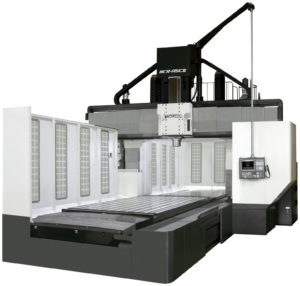

In addition to entirely new models, Okuma presented its wide product range of lathes, grinders, machining centres and multitasking machines with new features for already existing products. A true eye-catcher was the MCR-A5CII on display. The double column machining centre not only impresses with its enormous table working surface of up to 3,000 × 12,000 mm, but also with spindle speeds of up to 10,000 min-1 and AAC (Automatic Attachment Changer) which changes attachments within 30 seconds. The different attachments allow for true 5-sided applications making it the perfect solution for die and mould jobs.

In addition to entirely new models, Okuma presented its wide product range of lathes, grinders, machining centres and multitasking machines with new features for already existing products. A true eye-catcher was the MCR-A5CII on display. The double column machining centre not only impresses with its enormous table working surface of up to 3,000 × 12,000 mm, but also with spindle speeds of up to 10,000 min-1 and AAC (Automatic Attachment Changer) which changes attachments within 30 seconds. The different attachments allow for true 5-sided applications making it the perfect solution for die and mould jobs.

Additive and subtractive in one machine

Another centre of attention at the stand was the MU-8000V-L LASER EX, a super multitasking machine that combines additive manufacturing methods with subtractive technologies. Equipped with a TRUMPF laser, the machine is capable of adding metal via laser metal deposition (LMD) technology which supplies powder from nozzles and performs laser melting and bonding to the workpiece. The laser can also be used for surface treatments like laser-hardening of carbon steel workpieces.

Another centre of attention at the stand was the MU-8000V-L LASER EX, a super multitasking machine that combines additive manufacturing methods with subtractive technologies. Equipped with a TRUMPF laser, the machine is capable of adding metal via laser metal deposition (LMD) technology which supplies powder from nozzles and performs laser melting and bonding to the workpiece. The laser can also be used for surface treatments like laser-hardening of carbon steel workpieces.

Software for smart manufacturing

Besides the various machine tools, Okuma presented many IT and smart factory solutions. Okuma’s new Connect Plan provides analytics for improved utilization by connecting machine tools and enabling visual control of factory operations and machining. The software-based system monitors and collects data to fine-tune processes and improve productivity. The OSP control (accommodations can also be made for non-Okuma controls) connects to a PC installed with Factory Monitor suite. This enables machine operation status to be visible from the shop floor, office or the smartphone.

Monitoring and tracing

The Okuma NET BOX suite-S (Optional) plugs Connect Plan into the internet to show the operating status of a factory. Email notification of machine alarms can be checked, and the Okuma NET BOX suite-C (Optional), even connects to machines from other builders. Connect Plan achieves machining traceability by tying together the individual ID of a machined workpiece with the machining results and gauging results for each machine. If a problem occurs, the cause can be analysed and higher-quality production can be reinstated with greater assurance. Okuma’s remote diagnostics allows the screen from a customer’s machine to be viewed by a service technician for accurate communication.

Simulating processes in advance

While Connect Plan offers perfect control over the production process in whole, Okuma also presented 3D Virtual Monitor (3DVM), an IT solution that improves functionality of the individual machine tool. The software offers an accurate simulation of the machining process. By using the exact specifications of the Okuma machine, 3DVM determines in advance weather a program will run as safely, accurately and quickly as possible. It not only increases overall productivity but also prevents errors that may cause costly downtimes. In addition, 3DVM allows for safe tool change indexing, easy cut-off and simulations of complex milling machining operations as well as quick and easy simulations of turret synchronisation.