OEMs that make parts or products from flat-rolled steel, aluminum and other metals are eliminating in-house lamination operations and outsourcing to experienced coil coaters instead.

For OEMs that apply laminate films to metal parts or apply coatings to as decorative finishes, the in-house manufacturing process requires a significant investment in equipment, plant floor space and ongoing maintenance for what can be a very temperamental process. Not only that, but failure to precisely control what can be a very temperamental process can lead to laminates which do no bond properly or wrinkle, leading to excessively high scrap rates and even product returns. For this reason, OEMs are increasingly outsourcing the application of laminate films to experienced coil coaters who can provide several alternatives: steel, aluminum or other metals in coil or sheet form with pre-applied (dry) adhesive; or fully laminated product that eliminates in-house processing altogether. The result for OEMs can be significant, both in terms of speeding production and reducing operational costs. However, when paired with the fact that experienced coil coaters can produce high quality laminated products, it becomes a win-win scenario.

“Many OEMs are not fully aware of the alternatives for outsourcing part of, or all, the lamination operation to coil coaters,” explains Dan Chin, president of Universal Chemicals & Coatings (Unichem), a company that specializes in custom adhesives and coatings used in coil processing. “This is often simply because they have ‘always done it the same way’ – in house – but they can get a high quality laminated product and eliminate the costs and headaches associated with the process.”

Laminates

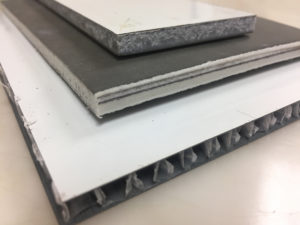

The use of laminate applied to metal to fabricate parts or products is widespread throughout manufacturing. Decorative finishes provide the look of stainless steel, brushed copper, and wood grains, as well as a variety of colors, imprints, and a range gloss levels. Laminate films can also serve a functional purpose by providing scratch or chemical resistance. Some of the more common applications including appliances (refrigerators and freezers, washing machines, dishwashers, microwaves, range or fume hoods), construction products (insulated wall panels, garage doors, roofing products) and the mobile and manufactured home markets (walls, door panels). Applying laminates to metal requires multiple steps. First, the metal is prepared by chemically cleaning and pre-treating. A liquid adhesive or film laminate is then applied to the metal and cured in an oven. The laminate film is then bonded to the metal as the adhesive coated metal exits the oven and the laminate is fed into nip rollers to join the laminate to the adhesive. The laminated metal is then cooled.

The use of laminate applied to metal to fabricate parts or products is widespread throughout manufacturing. Decorative finishes provide the look of stainless steel, brushed copper, and wood grains, as well as a variety of colors, imprints, and a range gloss levels. Laminate films can also serve a functional purpose by providing scratch or chemical resistance. Some of the more common applications including appliances (refrigerators and freezers, washing machines, dishwashers, microwaves, range or fume hoods), construction products (insulated wall panels, garage doors, roofing products) and the mobile and manufactured home markets (walls, door panels). Applying laminates to metal requires multiple steps. First, the metal is prepared by chemically cleaning and pre-treating. A liquid adhesive or film laminate is then applied to the metal and cured in an oven. The laminate film is then bonded to the metal as the adhesive coated metal exits the oven and the laminate is fed into nip rollers to join the laminate to the adhesive. The laminated metal is then cooled.

According to Chin, in each step of the process there can be challenges which can lead to poor bonding or delamination.

“All kinds of things can happen during a non-continuous laminating process,” says Chin. “You can have issues with bonding caused by the cleanliness of the metal, improper application of the adhesive or insufficient oven temperatures. There could also be misalignments of the laminate that cause wrinkles in the film.”

Chin says this can lead to extremely high scrap rates in excess of 20%. Worse than that, OEMs may experience product returns and negative reviews due to delamination that occurs on a delayed basis once the product is in the field.

“If there is an issue with the bonding of the laminate, it can manifest later when a product is already in the hands of the customer,” says Chin. “Normally there would be quality control testing in place to ensure that doesn’t happen, but it is still possible. By the time the OEM finds out, it can become quite costly.”

Outsourcing to Coil Coaters

According to Chin, one option for OEMs is to turn to experienced coil coaters who can pre-apply B-stage adhesive to virtually any metal substrate. The B-stage adhesive is designed to reactivate and cure within a specific temperature range to bond the laminate. This eliminates several steps and can lead to a higher quality laminate bond. “From a quality standpoint, you are going to get excellent uniformity of the adhesive applied [by a coil coater] and it will be properly cured,” says Chin. “Then, basically all the OEM has to do is laminate the film to the metal.”

Another option is to eliminate the entire process completely. This eliminates the need for in-house labor, application equipment, curing ovens, and environmental emission control systems.

“Typically, the coil coater has a lot of experience running these types of products, so they can dial in the adhesive thickness and control the curing and laminating temperatures very closely to ensure the proper bond,” says Chin. “That is going to translate to higher quality laminated product.”

Coil coaters must also guarantee scrap rates below a certain level.

“There is no testing the OEM will need to do, other than spot checks for their own quality monitoring process. The coil coater takes care of all that,” says Chin.

Chin adds that laminated coil can also be easily cut to just about any size, ready for stamping, forming or other finishing operations. This can eliminate several additional in-house steps and simplifies the process of maintaining an inventory of laminated metals in different sizes.

Adhesion challenges

Experienced coil coaters are also better equipped to handle difficult adhesion challenges, often with the help of adhesive formulators like Unichem that can deliver custom formulations and provide other advice about the lamination process.

Experienced coil coaters are also better equipped to handle difficult adhesion challenges, often with the help of adhesive formulators like Unichem that can deliver custom formulations and provide other advice about the lamination process.

“As an adhesive formulator, we can customize the adhesive to match more exactly what the OEM is trying to accomplish,” explains Chin. “There are times the adhesive company, which has a specific catalogue of products, doesn’t have a solution that works for specific applications.”

One example is adhesives formulated to be more “forgiving” in terms of temperature curing ranges. This can help OEMs that have challenges with oven temperature or consistency across the width of the coil.

“By working with the OEM or coil coater and understanding the parameters, we can help to dial in a solution that is very specific and resolve problems they are having in the bonding process,” says Chin.

Popular laminate films like TPO (Thermoplastic olefin) are also notoriously difficult to bond to metal. TPO can refer to materials such as polypropylene (PP), polyethylene (PE), block copolymer polypropylene (BCPP) and others. Although there are standard adhesives used to laminate to TPO, Chin says Unichem has seen enough variances that they have developed several custom solutions specifically designed for that material.

“As we have been formulating for TPOs, we have learned there can be really specific requirements as to the performance criteria and type of testing required that we have had to modify the adhesive significantly in order to get it to work for all the parameters,” says Chin.

Electrolytic Tinplate is another good example of a substrate that can be difficult to bond laminates and achieve the desired adhesion.

“Tinplate surfaces are very heat sensitive. Cure temperatures and other processing steps need to stay below 410 F, or within a 390 – 410 degree Fahrenheit range, otherwise tin re-flow can occur,” says Chin. This means that adhesives also need to cure or bond at temperatures below this temperature.

Time to make the switch?

Chin says that a good time to consider the transition is for plants that are utilizing aging equipment that can be time-consuming and costly to maintain or when scrap rates or performance issues with in-house laminating are excessively high.

“If the [lamination] equipment is 10 or 15 years old, it can become more problematic and require increasingly more maintenance. Outsourcing the entire process to coil coaters might be a better alternative than upgrading the equipment, which could be a huge investment,” says Chin

“Certainly in a manufacturing facility, the process of laminating can become a production bottleneck,” says Chin. “Because depending on the temperatures and thickness of the metal substrate, you can only process it a certain speed.” In some cases, outsourcing lamination operations – particularly those that are proving difficult and time-intensive – can speed up overall production.

“OEMs no longer have to worry about that if they receive laminated product in the sizes needed. They can immediately move to forming and finishing steps and definitely speed up production significantly if the laminating bottleneck is eliminated,” adds Chin.