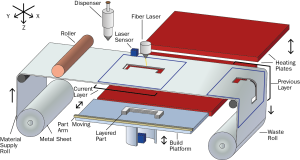

Additive Manufacturing (AM) technologies were initially proposed for rapid prototyping applications, with the target of obtaining a fast production of prototypes with low costs and short times compared to conventional technologies. Recently, the technological development has led to a high versatility of such processes in various industrial sectors, for instance automotive, aerospace, biomedical and energy, for functional parts and mass productions. Additive manufacturing technologies allow opening new productive possibilities. Nevertheless, they issue new challenges that must be faced to be able to exploit AM potentials fully, including the problems connected with the quality control and monitoring. Some researchers have proposed a new additive manufacturing process, called Composite Metal Foil Manufacturing, introduced and used to produce specimens for tensile testing. Three tests were carried out, the first two were executed on specimens by analysing the peeling and corrosion effect on Al99.5 sheets. The third test evaluates the force of aluminium/copper composites. Results show that the peeling and corrosion rate did not exert a significant effect on resistance. The attained results prove to be consistent with the previous tests, demonstrating that the performances of the new process remain equally effective. The tensile testing demonstrates that the part produced by the proposed process is 8% stronger than a part machined by a solid aluminium block. Outcomes prove that the process can produce constant and strong results compared to conventional machining methods.

Source: Javaid Butt; Habtom Mebrahtu; Hassan Shirvani, “Peel and tensile test investigation of aluminium 1050 foil parts made with a new additive manufacturing process”, International Journal of Rapid Manufacturing (IJRAPIDM), Vol. 5, No. 1, 2015. DOI: http://dx.doi.org/10.1504/IJRAPIDM.2015.073550