Laser cleaning uses a focused laser beam that is moved over the area to be cleaned by a scanner and machine axes. All the particles present – whether oils, oxides, paints, or technical coatings – can be removed in this manner, and the reaction products are then extracted by suction.

Parameters like the output and pulse frequency of the laser, its feed motion and track width as well as the machining time are precisely adapted to the degree of soiling and the desired level of cleanliness. As a result, the machine only processes defined areas like welds, glue joints, contact pads, and much more.

The rest of the component remains untouched, which keeps running costs very low. In contrast, washing processes permanently consume energy to keep the washing solution at a specified temperature. They also require additional drying and flushing processes that slow down the entire production process and are also susceptible to faults. Laser cleaning has none of these problems.

Complete solution in a very small space

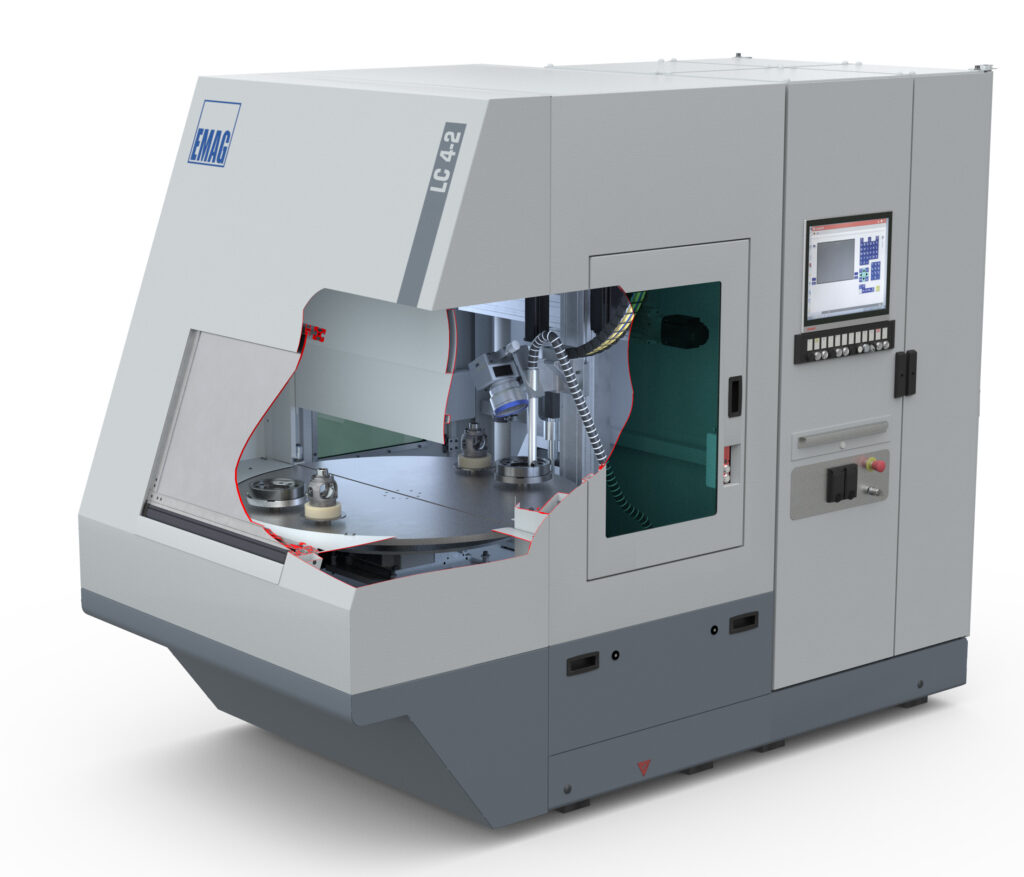

The specialists at EMAG LaserTec have built perfect mechanical engineering solutions for this effective process for some time now. The core of the solutions is the LC 4 laser cleaning machine for components with a diameter not exceeding 200 millimeters. It includes all the components needed for the process, in a space of just 4.5 square meters.

Efficient operations are ensured by a highly efficient 200 W laser that is only switched on for a few seconds for each component. The very short pulse duration ensures an equally short interaction time, which keeps surface damage to a minimum. The short pulse duration also enables high pulse peak power if needed. In turn, this property can be used to achieve certain surface properties on the component, such as improved adhesiveness.

The machine can be used in end-to-end production lines as well as alone. To this end, it features a turntable that is separate from the work area. It is loaded and unloaded by an automation system (or just manually) without interrupting operation.

Optionally, two components can be clamped simultaneously, while two others run through the cleaning process. This results in decreasing throughput times and no interruptions in the material flow. The modularity of EMAG mechanical engineering – creating customer-specific system solutions with building blocks — is the key to its success. This means that the high-quality components used are well proven. This goes for the LC 4, too.