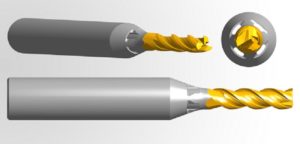

The small drill CrazyDrill Cool SST-Inox enables drilling Ø 1 – 6 mm to a depth of up to 20 x d without pecking. This is possible by the tool integrated helicoidal coolant ducts with their innovative drop shape, which deliver massive and constant coolant streams when drilling. Also, a new geometry with a chip-breaking effect in the front section of the flutes and an open flute profile in the back afford a perfect evacuation of the tiny chips. The range of milling cutters

The small drill CrazyDrill Cool SST-Inox enables drilling Ø 1 – 6 mm to a depth of up to 20 x d without pecking. This is possible by the tool integrated helicoidal coolant ducts with their innovative drop shape, which deliver massive and constant coolant streams when drilling. Also, a new geometry with a chip-breaking effect in the front section of the flutes and an open flute profile in the back afford a perfect evacuation of the tiny chips. The range of milling cutters

CrazyMill Cool is being expanded with a four tooth VHM finishing mill diameter range 1 – 8 mm for depths up to 5 x d and a milling head of 2 x d. Cooling channels, integrated in the shaft of the tool deliver a constant coolant flow. Even with aggressive chip removal the cutting edges do not overheat. A surface close to grinding quality is achieved. Specially for the medical technology (implants) milling head lengths of up to 4 x d are available. With the progressive flutes (from 30º to 40º) milling without vibrations, which improves surface quality even more, is guaranteed.

Boremill CrazyMill Cool Ø 1 – 8 mm when milling depths of 2 x d enters up to 1 x d perpendicular into the material (drilling) and then progresses laterally to machine grooves and pockets in solid material. It collects chips while drilling in its expanded chip collection section in the tool’s head and then evacuates chips through the large flutes. Stable and robust cutting edges into the center of the tool prevent vibrations. Integrated coolant ducts provide a constant and massive cooling of the cutting edges. This prevents overheating of cutting edges which in turn results in long tool life and high chip removal rates.

Exhibiting at EMO Hannover: Hall 4 Stand A74