The upcoming editions of Mecspe (the international trade fair for the manufacturing industry which will be held in Parma from March 23 to 25) and Technology Hub (the professional event for innovative technologies which will take place in Milan from April 20 to 22) will once again provide an opportunity to see the ultimate innovations for the industrial and professional environments live. As part of the previous exhibitions, among other numerous demos going on at booths, visitors were able to view live all the manufacturing stages of a gadget in the Manufacturing with 3D printing area – from CAD modelling to product manufacturing using injection moulding, through to mould made on the spot in real-time with 3D printing.

The upcoming editions of Mecspe (the international trade fair for the manufacturing industry which will be held in Parma from March 23 to 25) and Technology Hub (the professional event for innovative technologies which will take place in Milan from April 20 to 22) will once again provide an opportunity to see the ultimate innovations for the industrial and professional environments live. As part of the previous exhibitions, among other numerous demos going on at booths, visitors were able to view live all the manufacturing stages of a gadget in the Manufacturing with 3D printing area – from CAD modelling to product manufacturing using injection moulding, through to mould made on the spot in real-time with 3D printing.

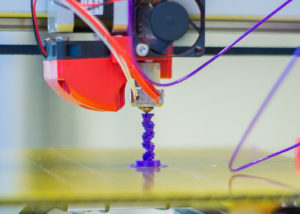

An initiative that will be repeated in the Additive Manufacturing 4.0 area “From project to object – Creating and manufacturing by combining different technologies and materials” during the 2017 editions of the two events. At Mecspe and Technology Hub, you will again be able to witness live all the creation steps of an object, which in this case will be obtained by combining two parts of different materials (opaque and transparent, rigid and flexible) that will be assembled at the end of two printing processes involving the use of two distinct professional 3D printing technologies. This way you will get the chance to see the potential of additive manufacturing directly on the spot, checking the actual printing time, the resolution of the manufactured objects, the materials employed by touching (and taking as souvenirs) the pieces just “churned out” by 3D printers. Printers will be running throughout the two events and manned by technical and sales staff able to answer any visitors’ questions.

A part of the area will be devoted to the software which makes it possible to build object models and prepare them for 3D printing. Also in this case, stations will be always manned by CAD modelling and additive manufacturing specialists who will clarify any doubts you may have about the design and development stages. The demo area will finally also feature a number of stations assigned to partner magazines and university research partners specialised in materials and industry 4.0.